Metal Cutting Equipment from Lockformer

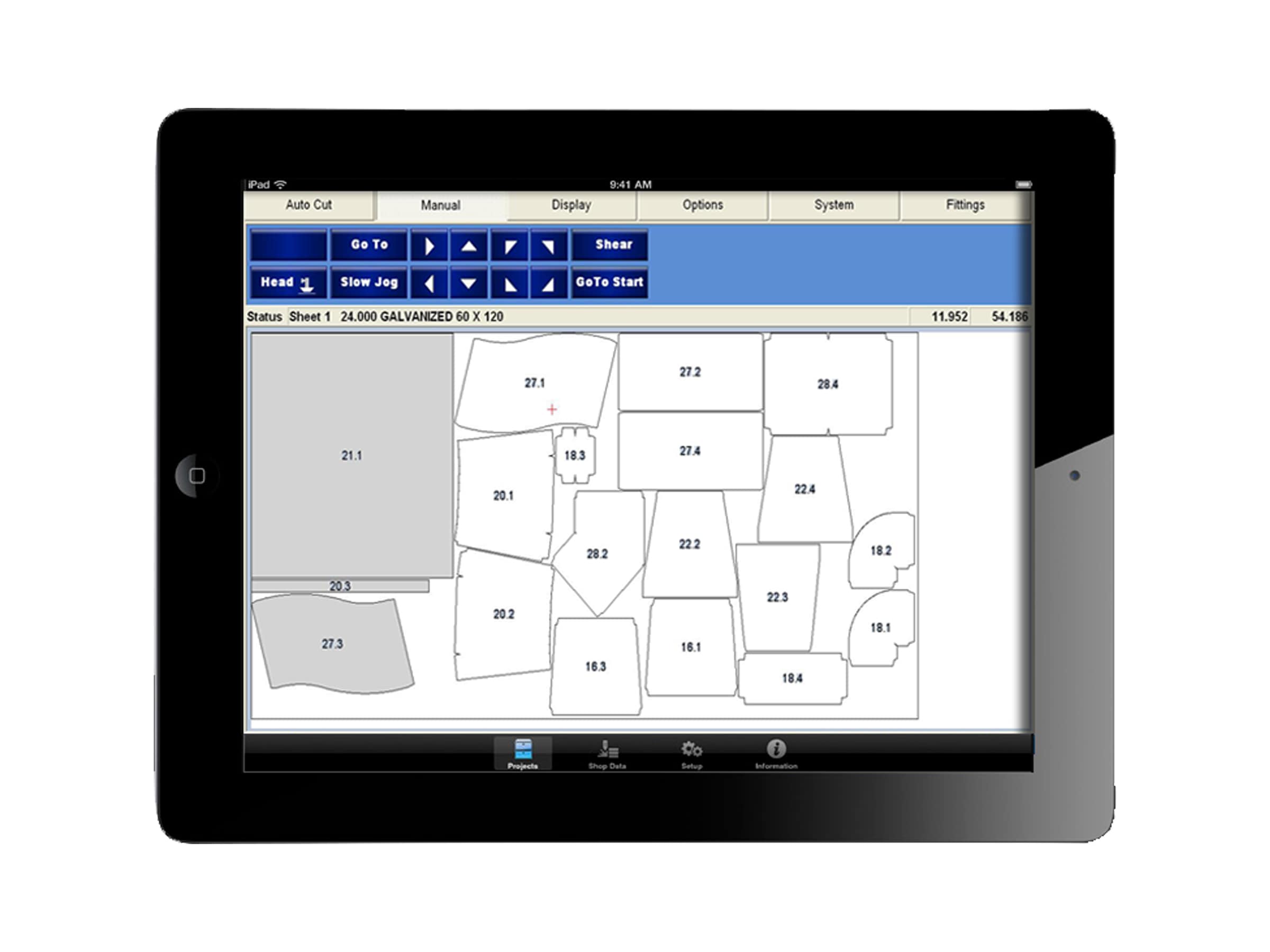

Lockformer has long been the industry leader in HVAC sheet metal cutting systems and has helped revolutionize the production of HVAC duct fittings. Our history in metal cutting goes all the way back to 1982 with the groundbreaking VulcanPlus Sheet Metal Plasma Cutting System which is still renowned for its design and CAD to CAM solution and continues to outperform all other plasma cutting systems in the market with its ease to use, versatility in cutting a wide range of material thicknesses, 1safe cutting environment, faster cutting, and smaller footprint. In 2016, Lockformer introduced the Vulcan Laser-Max 1.5 Coil Fed Sheet Metal Laser Cutting System — and there aren’t many limits for what this machine can do. Fast, accurate, and able to cut multiple thicknesses and densities, the Laser-Max 1.5 offers a cleaner and more efficient way to cut metal with low to no fumes, using less heat, creating superior fine edges, and eliminating downstream processes like deburring and grinding. With minimal to zero exhaust in a 3-zoned table system, the Laser-Max eliminates the need to clean fittings after cutting and the patent-pending technology allows operators to access parts directly from the table eliminating the need for a pallet shuttle system.

Lockformer has changed how the sheet metal industries cut metal — and its why sheet metal operations wanting to gain an edge over their competitors choose Lockformer for sheet metal cutting machinery. For your review, below are all the machine and equipment solutions available from Lockformer for Metal Cutting — please don’t hesitate to reach out if you have a particular application or operational requirement that might require a customized solution… we’d love to help.

Featured Lockformer Machine

Lockformer Metal Cutting Machinery and Equipment

Schedule a 1-on-1 Consultation with a Lockformer Technical Advisor

For over 75 years, Lockformer has been the most recognized name in the sheet metal machinery industry — leading the world in the production of HVAC duct and fittings fabrication equipment solutions including insulation cutting equipment, metal cutting systems, rectangular, round, and oval ductwork roll forming equipment, and HVAC CAD to CAM software Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with a Lockformer Technical Advisor today.

We're Here to Help

Have questions about Lockformer machinery and equipment? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs to evaluate if your project can be justified? Please don’t hesitate to reach out — we’d love to help.