Produce Finished HVAC Duct with Less Chance of Leakage with the Iowa Precision ProFabriduct Full Coil Line

Full-Width Longitudinal Seam Substantially Reduces the Chance of Leaks

The ProFabriduct Full Coil Line from Iowa Precision is the most advanced complete coil line in the HVAC industry today. The line leverages footprint, speed, and production rates along with tolerances that no other HVAC coil line can match.

And now, the Iowa Precision ProFabriduct Full Coil Line has been redesigned and re-engineered to produce Pro-Duct™ — a finished duct with a full-engagement longitudinal seam which substantially reduces the chances of leakage in the corners of the duct’s transverse joint by up to 25% in most cases.

With the ProFabriduct Full Coil Line, you can produce a better product (one with tangible benefits for your customers) while reducing your post-production labor costs — that’s a competitive advantage you can take to the bank.

Schedule a no obligation, 1-on-1 Consultation with an Iowa Precision Technical Specialist today and let’s discuss how the ProFabriduct can be a game-changer for your operation.

Full-Width Longitudinal Seam Production:

What’s the Difference and Why Does it Matter?

The Full-Width Longitudinal Seam

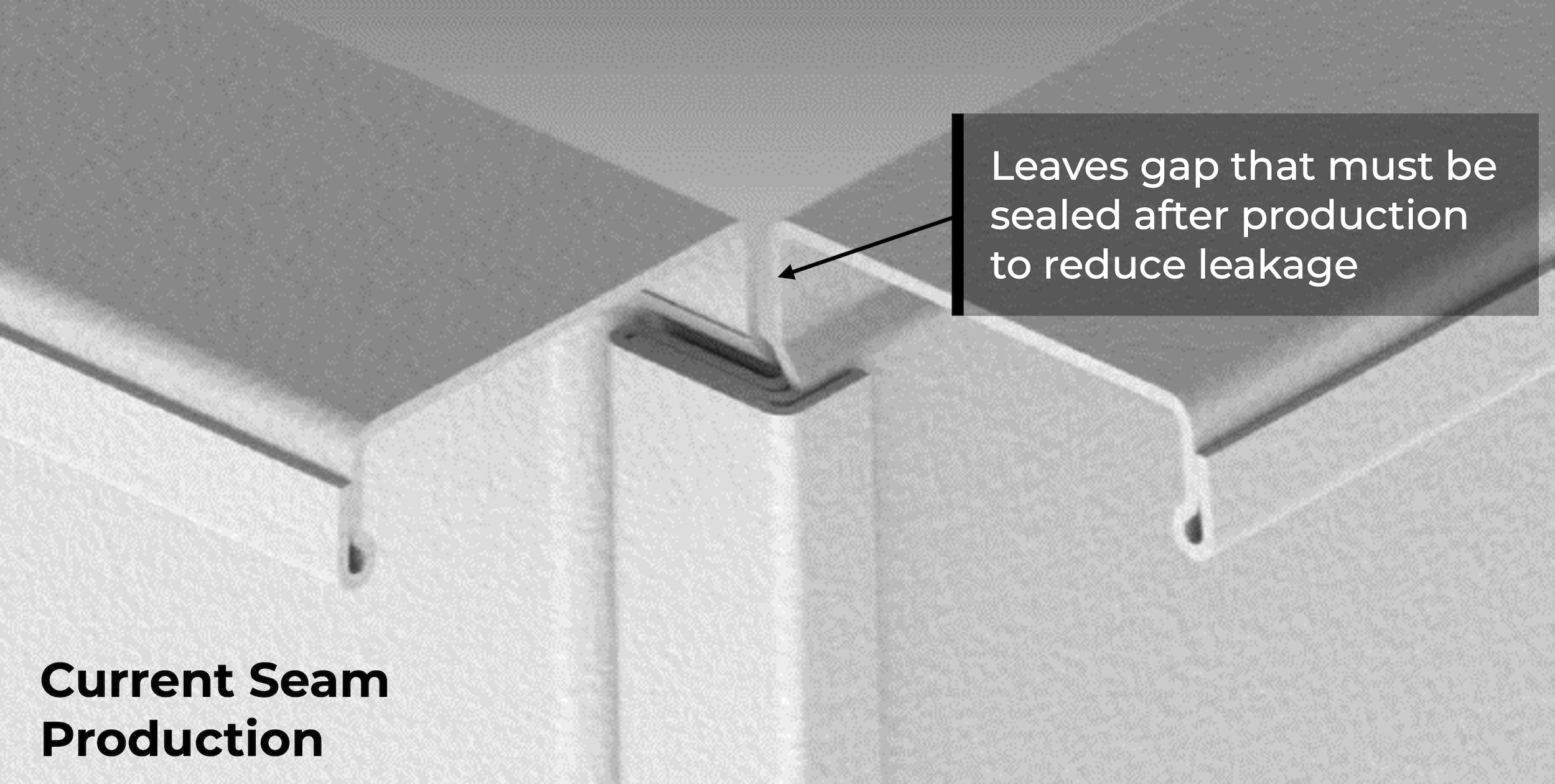

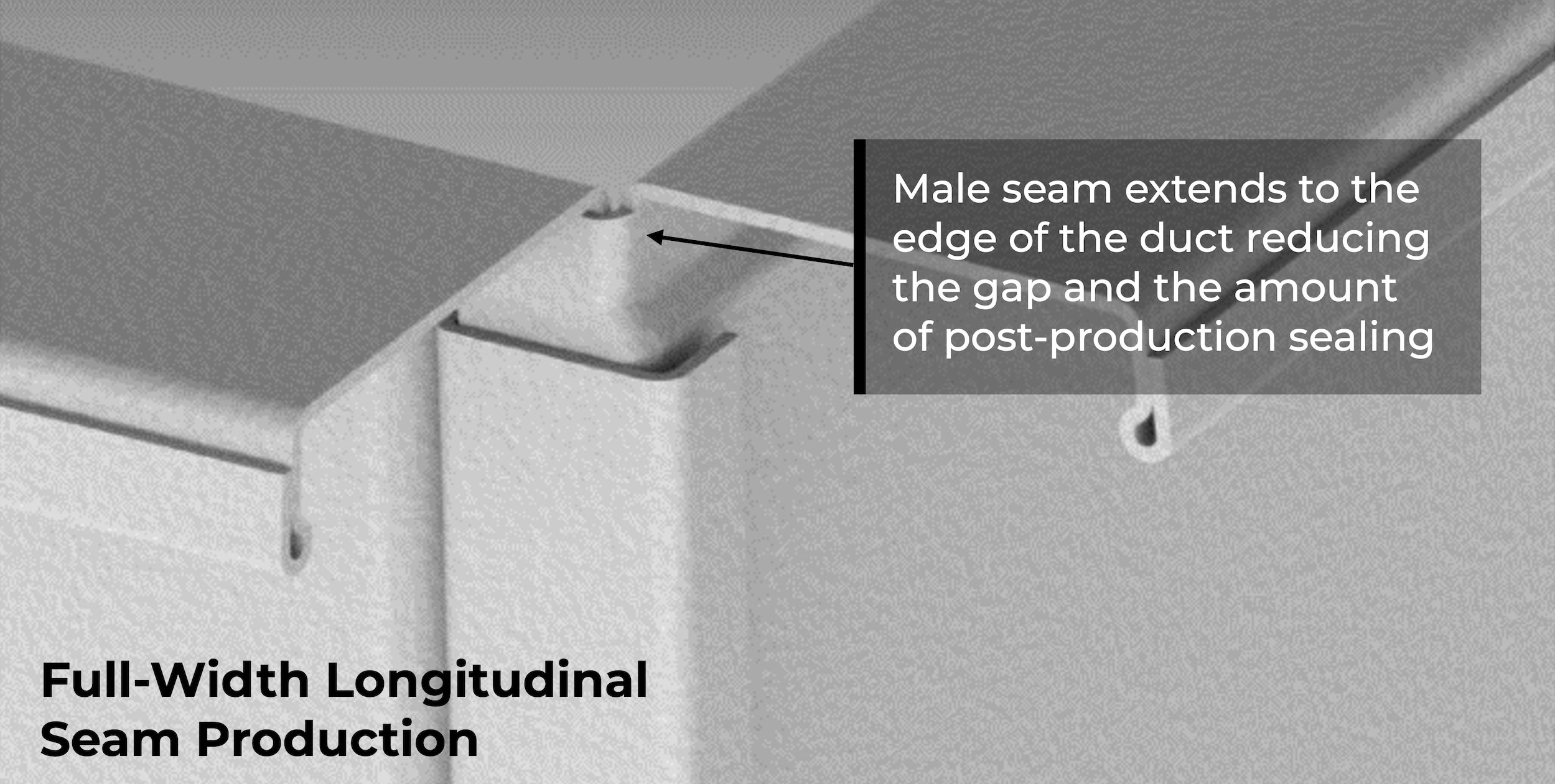

Most HVAC duct leakage occurs at the notch hole that is produced at the top and bottom of a duct section at the transverse duct connection to the fan or the unit. The Iowa Precision ProFabriduct Full Coil Line has undergone a combination of modifications to the processor, transfer system, and hydraulic servo wrap brake that allow it to produce a full-engagement longitudinal seam which allows you to deliver a finished duct with substantially reduced chances of leakage in the corners of the duct’s transverse joint. Not only does the reduced chances for leakage create a more desirable duct, but it also reduces the amount of post-production sealing that’s necessary.

The Full-Width Longitudinal Seam Production is applicable to our 5’ line, with 4’ or 5’ stock, and can be either Large-Pittsburgh and Small-Pittsburgh or Large-Pittsburgh and Snaplock.

The notch profile is altered to leave more material on the male side of the notch, allowing the male seam to extend to the edge of the duct. Dual stepper-motor controlled notching die positioning eliminates an operator from needing to adjust the notchers for coil width or notch type; precise positioning is handled through the control system. The 90˚ male lock is formed after the roll forming of the connecting flange, avoiding the full length male flange from being deformed as it passes through the roll former. The servo wrap brake is altered to include locating pins to accurately locate the part parallel to the bending beam. Positioning of the leading raw edge gives very accurate and precise locations for the subsequent bends. Computer controlled leaf tooling gags have been added allowing the brake to bend the full engagement male lock seam without deformation.

Our testing in conjunction with SMACNA has shown that the Full Width Longitudinal Seam Ducts produced with the Iowa Precision ProFrabriduct Full Coil Line demonstrate a 25% reduction in the chance of leakage across different gauges and different size ducts. Request a consultation today to see the test results.

Prefabrication continues to be the growing trend across the country. Pre-assembling ductwork in a controlled environment prior to shipping leads better to quality, just in time fabrication, less inventory on the job site, and a significant reduction in labor costs. The innovative ProFabriduct Full Coil Line from Iowa Precision was designed with this trend in mind — with features like a full-width inline plasma for taps, collars, and access doors all from shop detail drawings and much more. Request a consultation today with an Iowa Precision Technical Advisor and see how the Pro-Fabriduct Full Coil Line can dramatically enhance your prefabrication capabilities to give your operation a competitive advantage.

About Iowa Precision

For over 70 years, Iowa Precision has been the industry leader in the design and manufacturing of automated HVAC coil lines, duct fabrication systems, seam closers and corner inserters. Our wide range of solutions includes rectangular, round, and oval ductwork machinery, flexible fabrication systems, and coil processing machinery and equipment. Our advanced technologies are field-proven and guaranteed to outperform your most demanding expectations. Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with an Iowa Precision Technical Advisor today..

Request a 1-on-1 Consultation

Request your 1-on-1 consultation with an Iowa Precision Technical Advisor today and we’ll get back to you within 24 hours to schedule your consultation. There’s absolutely no obligation — simply an opportunity discuss how the Iowa Precision ProFabriduct Full Line can give you the competitive advantage you need to take your operation to the next level and answer any questions you might have.