Reduce Manual Labor for a Safer Workplace and Improved Duct Quality with Cornermatic Systems

Fully Automated Corner Insertion Solutions from Iowa Precision

Schedule a no obligation, 1-on-1 Consultation with an Iowa Precision Technical Specialist today and let’s discuss how the Cornermatic can maximize the productivity, profitability, and safety of your operation while improving the consistency of your quality.

Featured Cornermatic® Systems:

Cornermatic Plus Versa

Closes Duct Work in a Fraction of the Time

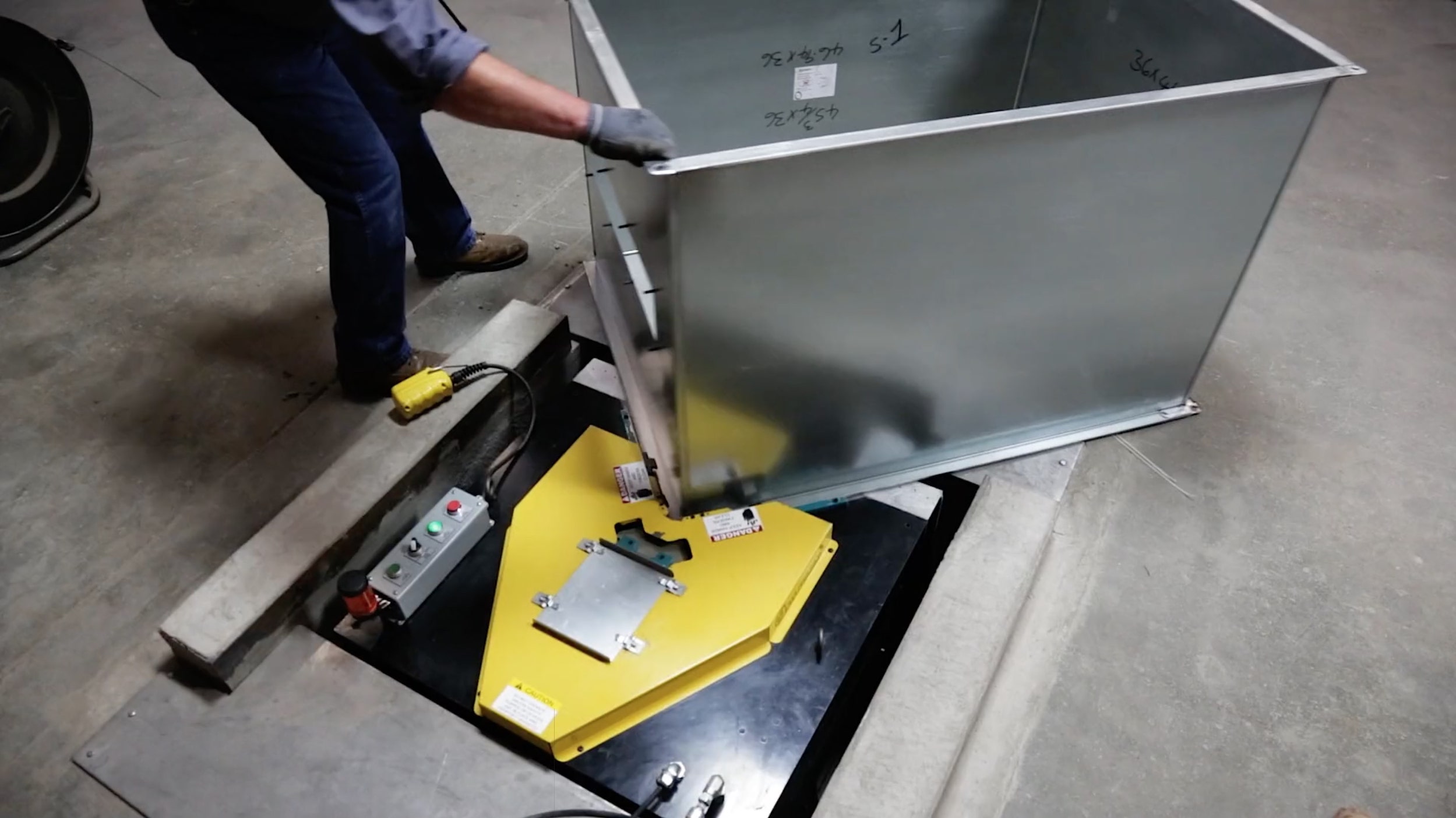

While the Iowa Precision Cornermatic Plus was designed to automatically insert corners into DUCT SECTIONS, the Cornermatic Plus Versa was specifically designed for the fabrication of duct FITTINGS. The system features an above ground, table height setting for fabricating small fittings and a floor level setting which allows for sliding over large duct sections and fittings (machine goes from in-ground to above ground in less than 1 minute with a simple push of a button). The Cornermatic Plus Versa completes eight (8) corner inserts — square and fully crimped — in any gauge (16-26) in approximately 20 seconds and can even handle odd fittings like tight square throat elbows, flex connectors, offsets down to 2″ throats, and even the toughest inside or outside angle off-set transition fitting from 16-26 gauge.

Hidden

Key Features

- Specifically designed to automatically and effortlessly insert corners in the fabrication of both small and large duct fittings in any gauge (16-26) — including tight square throat elbows and flex connectors, odd size fittings such as flex connectors and curbs, and even the toughest inside or outside angle off-set transition fittings

- Completes eight (8) corner inserts in approximately 20 seconds

- Corners are inserted square and fully crimped

- Above ground, table height setting is ideal for fabricating small fittings while floor level setting allows for sliding over large duct sections and fittings to automatically insert the corners — simple press of a button allows operator to go from in-ground to above ground setting in less than 1 minute

- No switches or foot pedals – just push in and Cornermatic Plus Versa does the rest

- Works with SMACNA-conforming, T-25a and T-25b flange and many other flanged duct systems without changing settings

Cornermatic II Whisper-Loc Combo

Corner Insertion and Seam Closing on One Machine

The Iowa Precision Cornermatic II Whisper-Loc Combo is a unique, innovative machine that not only inserts and crimps corners into both ends of ductwork but closes longitudinal Pittsburgh seams on the same ductwork when required. This design allows the operator to accomplish both corner insertion and seam closing on one machine without having to handle the ductwork between processes. The system completes eight (8) corner inserts — square and fully crimped — in approximately 20 seconds and will close the Pittsburgh seam on any ductwork that uses the duct flanges conforming to T25-a or T25-b under the SMACNA Duct Construction Standards. It will also close the Pittsburgh seam on ductwork that uses the raw edge or slip and drive method.

Hidden

Key Features

- Automatically inserts and crimps corners into both ends of ductwork that uses the transverse duct connector (TDC) or transverse duct flange (TDF) method of joining

- Pittsburgh seam closing on any ductwork that uses the duct flanges conforming to T25-a or T25-b or that uses the raw edge or slip and drive method.

- Requires only compressed air and 460/3/60 current to operate.

The Cornermatic® Family of Automated Corner Insertion Solutions

Schedule a 1-on-1 Consulation with an Iowa Precision Technical Advisor

For over 70 years, Iowa Precision has been the industry leader in the design and manufacturing of automated HVAC coil lines, duct fabrication systems, seam closers and corner inserters. Our wide range of field-proven solutions includes rectangular, round, and oval ductwork machinery, flexible fabrication systems, and coil processing machinery and equipment. Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with an Iowa Precision Technical Advisor today.

Request a 1-on-1 Consultation

Request your 1-on-1 consultation with an Iowa Precision Technical Specialist today and we’ll get back to you within 24 hours to schedule your consultation. There’s absolutely no obligation — simply an opportunity discuss how the Iowa Precision Cornermatic can maximize the productivity, profitability, and safety of your operation and answer any questions you might have.