Mestek Machinery Solutions for the Roof Curb Manufacturing Industry

Machinery and Equipment

HVAC Rectangular Duct and Fittings Fabrication Equipment

Round / Oval Duct and Fittings Fabrication Equipment

Spiral Duct and Fittings Fabrication Equipment

Flexible Fabrication Equipment

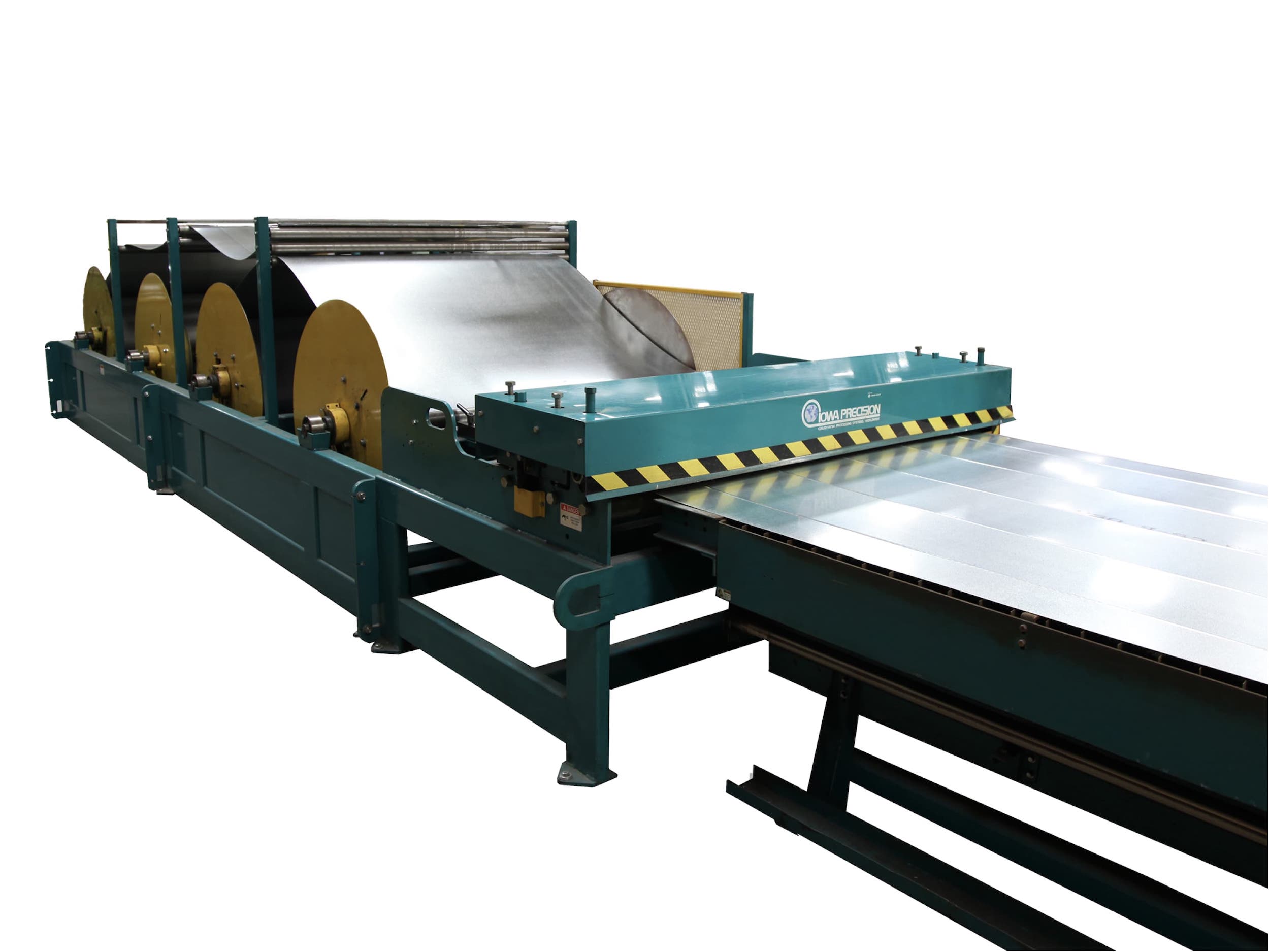

Coil Metal Processing Equipment

Metal and Insulation Cutting Equipment

Mestek Machinery and its family of brands have served the sheet metal and fabrication industry with advanced and labor saving sheet metal fabrication equipment and solutions for over 80 years. With nearly a century of experience of creating innovative solutions, Mestek Machinery continues to maintain its reputation for designing and manufacturing the most complete, productive, and state-of-the-art metal forming solutions for the fabrication of sheet metal products. Mestek Machinery provides automated solutions for the roofing curb manufacturing industry which help reduce waste, improve productivity, and produce better products.

Mestek Machinery portfolio of machinery and equipment solves the specific and unique challenges of the roofing curb fabrication industry. Our knowledge of the industry and our ability to develop cutting-edge technologies, and automated manufacturing equipment provides roofing curb manufacturers with solutions that save time, material, labor, and money all resulting in increased profitability. Our solutions meet the highest tolerances for precision, efficiency, and speed to deliver roofing curb products and components that you can proudly put your name on. Mestek Machinery doesn’t just provide equipment, we provide answers.

Learn more about the Solutions for the Roof Curb Manufacturing Industry from Our Brands

Featured Mestek Machinery Solution for the Roof Curb Manufacturing Industry

Mestek Machinery Solutions for the Roof Curb Manufacturing Industry

Schedule a 1-on-1 Consultation with a Mestek Machinery Technical Advisor

Mestek Machinery is comprised of a family of metal forming manufacturing brands with deep roots in the HVAC duct fabrication industry: Lockformer, Iowa Precision, Engel, and Roto-Die. Together, our brands design and manufacture the most complete, productive, and innovative metal forming solutions for the fabrication of HVAC sheet metal ductwork and fittings. With over 100 years of combined experience addressing every facet of the HVAC duct industry, our knowledge and experience allows us to develop cutting edge, precision technologies, and automated manufacturing equipment that saves sheet metal contractors and fabricators time and labor while ensuring a finished duct product of unmatched quality.

Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with a Mestek Machinery Technical Advisor today.

We're Here to Help

Have questions about our machinery and equipment? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs to evaluate if your project can be justified? Please don’t hesitate to reach out — we’d love to help.