LightWELD

Handheld Laser Welding & Cleaning Systems

LightWELD Handheld Laser Welding and Cleaning Systems from IPG Photonics are fast, easy to learn and operate, and produce high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.

- Adjustable laser welding power up to 1500W

- Preset & user-defined modes optimize material-thickness combinations

- Wobble welding controls for 5 mm of additional weld width

- Rear panel provides intuitive connections for power, process gas and external accessory controls

- Cleaning power up to 2500W peak for greater welding quality and finishing capability

Fast

Up to 4X faster than TIG

Versatile

Wide range of materials – up to 1/4 in. (6.35 mm)

Easy

Optimized presets reduce learning curve

Consistent

High-quality, repeatable results

Flexible

Simple and challenging applications

Productive

Pre- and post-weld cleaning capability

What Experienced Welders Say About LightWELD

Watch Paul Sableski from Weld.com demonstrate the features, capabilities and just how easy LightWELD XC is to set up and operate at “lightning speed.”

Paul uses LightWELD XC to quickly create:

- 3 mm Aluminum Butt Weld

- Stainless Steel T-Joint, 6 mm to 1 mm

- Stainless Steel Lap Joint with wire feeder

“This laser process is definitely the future in the Industry. It amazes me how fast it welds and the quality of weld it produces!”

Less Heat & Distortion than MIG and TIG Welding for More Productivity & Flexibility

TIG Welding

TIG welding is a time-consuming, two-handed method that requires an experienced, highly-skilled operator. It may generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses.

MIG Welding

MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.

LightWELD

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion, deformation, undercut or burn-through.

The low heat input and extensive material and thickness capabilities increase productivity, repeatability, and improve weld quality for operators of all skill levels. LightWELD welds dissimilar metals of different thicknesses with ease and creates aesthetic high-strength joints with minimal or no consumable wire. Plus, LightWELD XC and LightWELD XR offer built-in pre- and post-weld cleaning not found on any traditional system.

Factory Presets Ensure Optimized Welds & Cleaning

- Simple preset selection ensures consistent high-quality laser welds and cleaning

- Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

- Operators can instantly switch between presets to process multiple material-thickness combinations

- Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results

- Novice operators require less training which reduces labor costs while preserving quality, increasing productivity and decreasing scrap

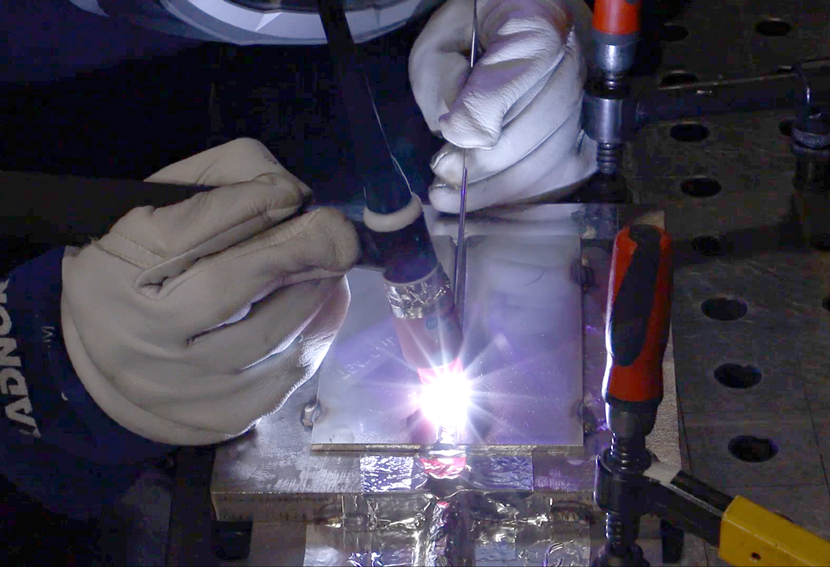

Easy to Learn and Operate

- Ergonomic, compact and proven to be the most comfortable and easy to use laser gun with built-in wobble welding functionality.

- 2-step trigger and part contact sensor enhance operator safety

- Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

- Quickly switch from standard laser welding to wire welding, and from laser welding to laser cleaning

- A single cable from the unit delivers laser power, gas and control connections to the gun

“In my 41 years in the business, I have never seen a welder that allows beginners to make welds like seasoned pros!”

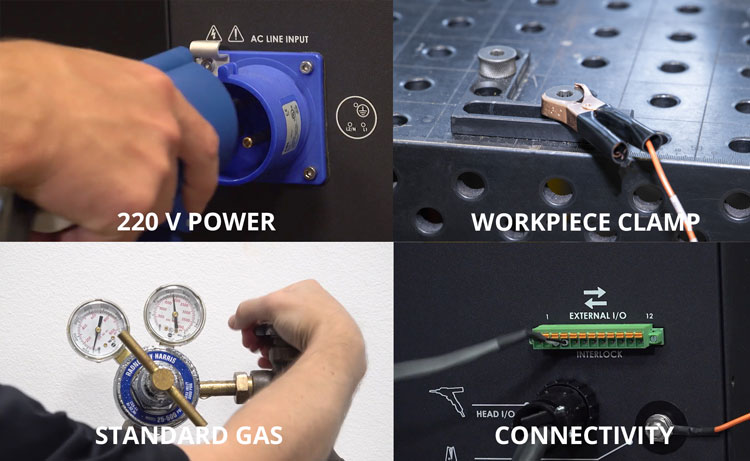

Fast and Easy Set-Up

- Clearly labeled rear connections make getting started fast and easy

- Simply plug in power cord and gas connection, attach clamp to work surface, and the system is ready to go

- Laser power, gas, and gun control are delivered through a single cable

- An ethernet computer connection provides access to advanced parameter settings to fine tune and save process parameters

Loaded with Operator Safety Features

- Key switch control to secure system from unauthorized operation

- Emergency-stop button for immediate shut down

- Safety interlock verifies integrity of laser delivery to the welding gun

- 2-step weld gun trigger, enable and then fire, for intentional operation

- Part contact electrical interlock turns off the laser power if the welding head is not in contact with the welded parts

- Door switch interlock circuits shut down laser if anyone other than operator unexpectedly enters the welding area

LightWELD is a Class IV laser system and safety precautions are required. Operator protective equipment including welding gloves, welding shield and 1070 nm laser-safe glasses are required.

Request a 1-on-1 Consultation

Request your 1-on-1 consultation with a Mestek Machinery Technical Advisor today and we’ll get back to you within 24 hours to schedule your consultation. There’s absolutely no obligation — simply an opportunity discuss how LightWELD can give you the competitive advantage you need to take your operation to the next level and answer any questions you might have.