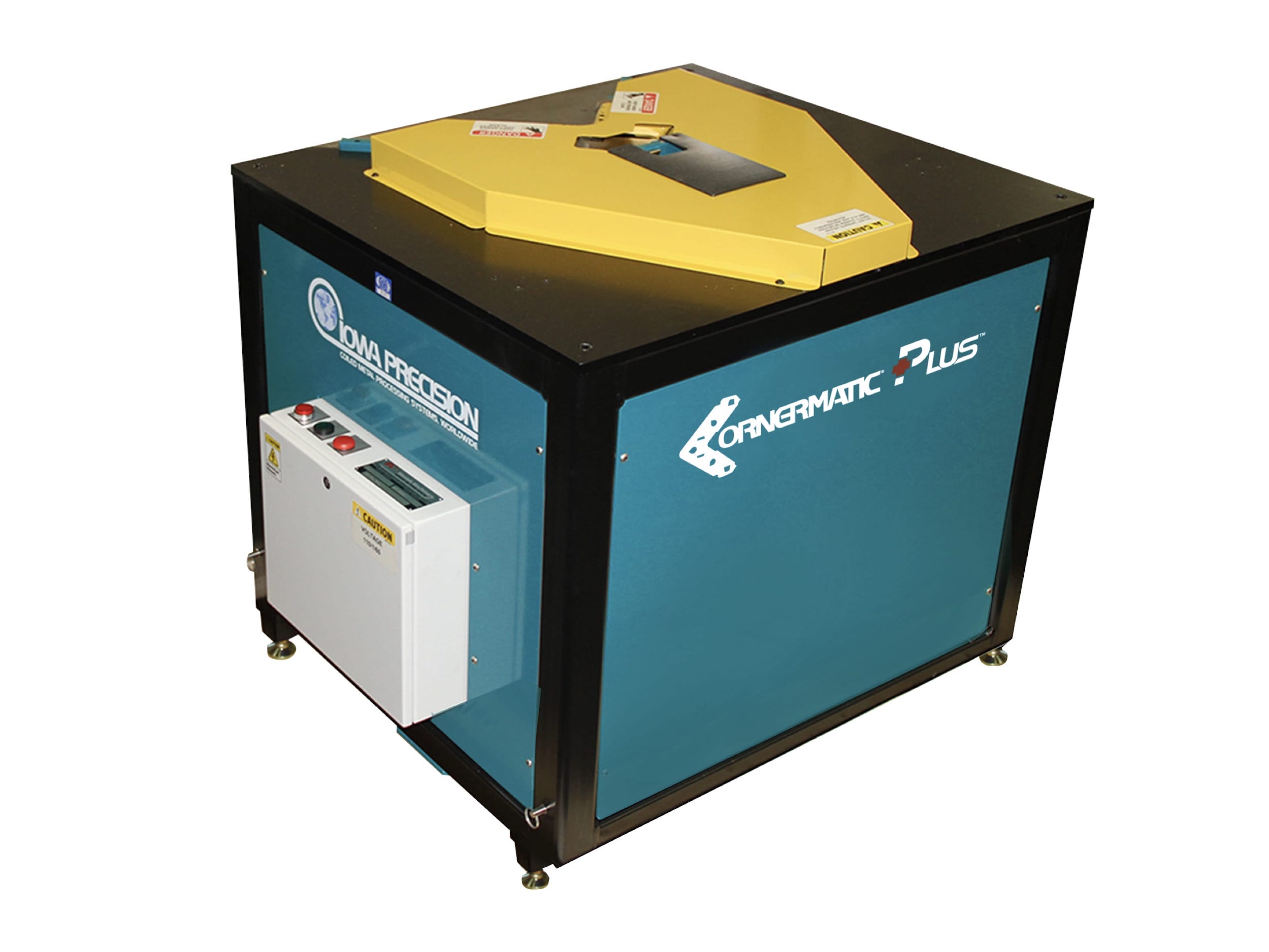

Iowa Precision Cornermatic Plus® Automated HVAC Ductwork Corner Inserter Machine

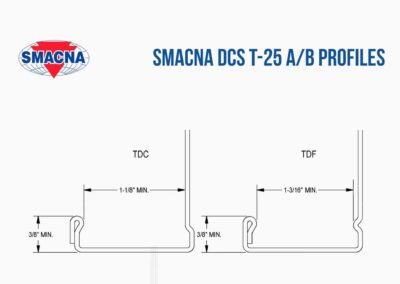

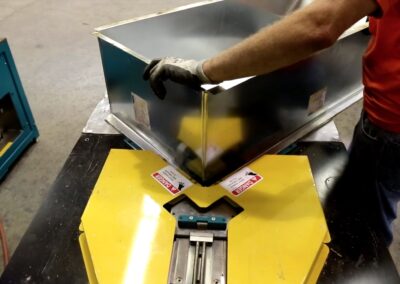

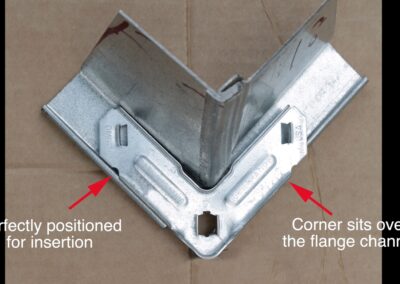

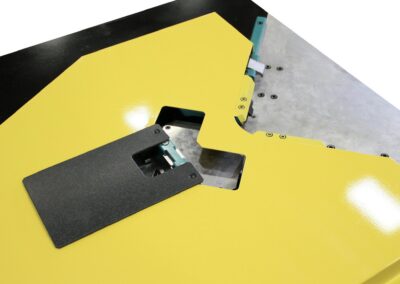

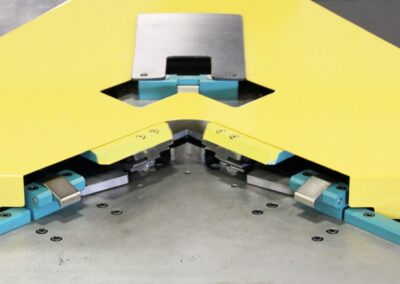

The Iowa Precision Cornermatic Plus Automated Corner Insertion Machine was specifically designed to reduce shop labor by addressing the difficulty with inserting corners into duct FITTINGS — from standard fittings to odd fittings like tight square throat elbows, flex connectors, offsets down to 2″ throats, and even the toughest inside or outside angle off-set transition fitting from 16-26 gauge. Sitting at an ergonomically comfortable table height, the Cornermatic Plus The Cornermatic Plus can handle any transverse duct connector (TDC) or transverse duct flange (TDF) fitting assembled on a bench and automatically and effortlessly completes eight (8) transverse duct connector (TDC) or transverse duct flange (TDF corner inserts — square and fully crimped — in approximately 20 seconds.

For additional flexibility, see the Cornermatic Plus Versa Automated Corner Insertion Machine which features the same above ground, ergonomic table height setting as the Cornermatic Plus, but also adds a floor level setting which allows for sliding over larger, heavier fittings and cut duct sections (machine goes from in-ground to above ground in less than 1 minute with a simple push of a button).