- One (1) #37 Roto-Die® with 7˚ cross-braking groove, 85˚ die opening 3/8″ wide, 85˚ die opening 7/8″ wide, 30˚ die opening 1/2″ wide

- One (1) #1 Forming Die 85˚

- One (1) #24 Hemming Die 30˚

- Six (6) sheet support arms with clips

- Six (6) #52 gauging blocks

- Six (6) #53 disappearing spring-pin gauges

Available options for Tooling and Dies from Roto-Die:

- Forming and Open Hemming Dies: forming and open hemming are accomplished with standard 30˚ upper die and #37 Roto-Die. Following these sequences, a standing lock seam may be formed without a die change or multiple handling of the sheet

- Louvre Blade Forming Dies: man degree-of-bend combinations are quickly and easily formed by bottoming and air-bending

- Architectural Gravel Stop Adapter Plate Dies: this combination die will for 120″ of 24-gauge gravel stop with a 3/4″ rise. Easy removal of the rear-forming section converts the die to acute-angle forming and hemming operations.

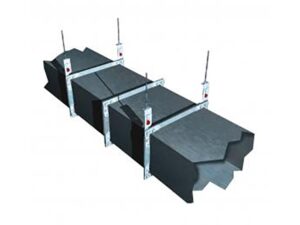

- Multi-Forming Dies: damper blades and V-rib shapes may be formed in one stoke in 20-gauge galvanized steel up to 120″ long. Shorter lengths may be formed in heavier gauges. The die is adjustable for metals with springback.

- Channel Forming Dies: 90˚ gooseneck dies (with or without angle inserts) simplify forming light and heavy-gauge channels.

- Box Forming: depths to 1-3/4″ may be formed with standard dies

- Heavy-Gauge Forming: machined inserts increase bender capacities up to 120″ of 10-gauge materials for heavy-gauge or large radius forming.

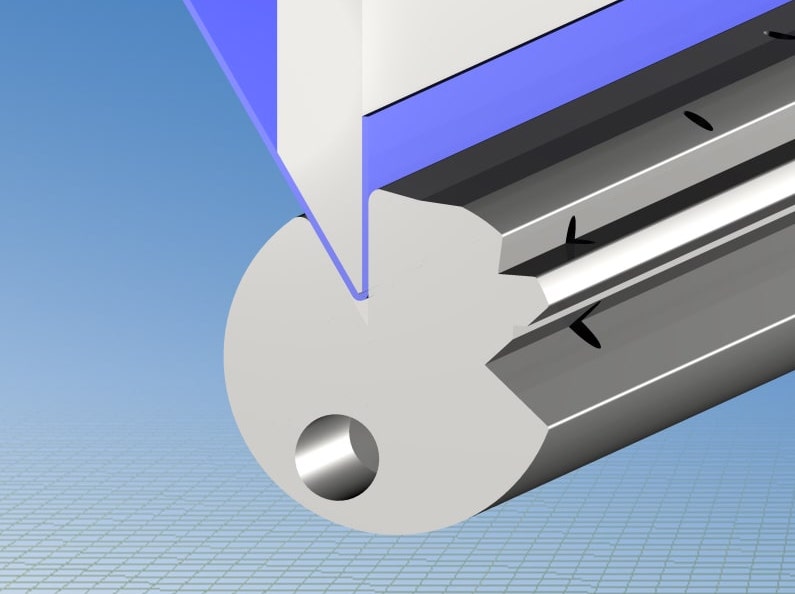

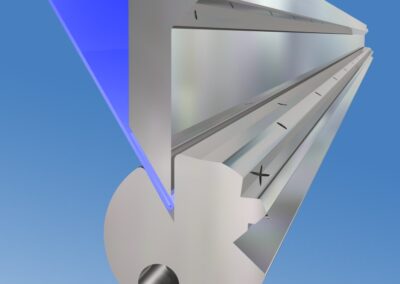

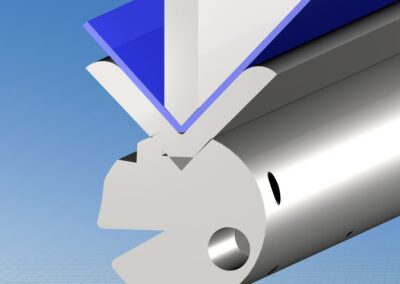

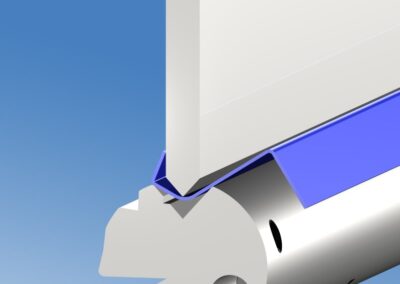

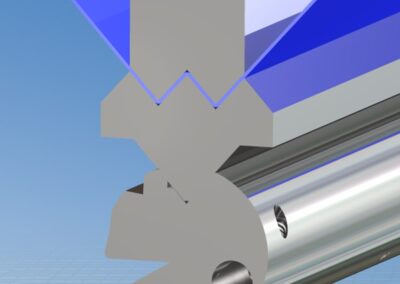

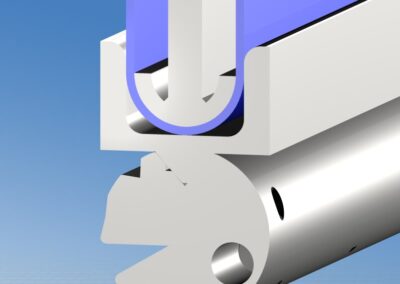

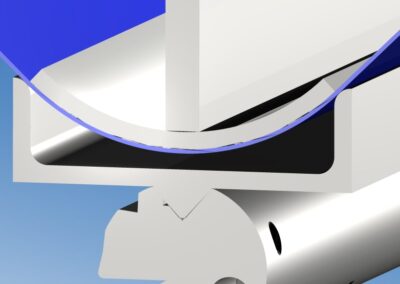

Here’s a look at some of our standard dies and some custom dies we’ve produced for existing customers:

Roto-Die | Press Brake Machine

Roto-Die | Press Brake Machine | Back Gauge Options

Roto-Die | Press Brake Machine | Indexible Lower Die

Roto-Die | Press Brake Machine | Tooling & Dies