Iowa Precision Solutions for the Commercial Low-Slope Metal Roof Fabrication Industry

Machinery and Equipment

HVAC Rectangular Duct and Fittings Fabrication Equipment

Round / Oval Duct and Fittings Fabrication Equipment

Flexible Fabrication Equipment

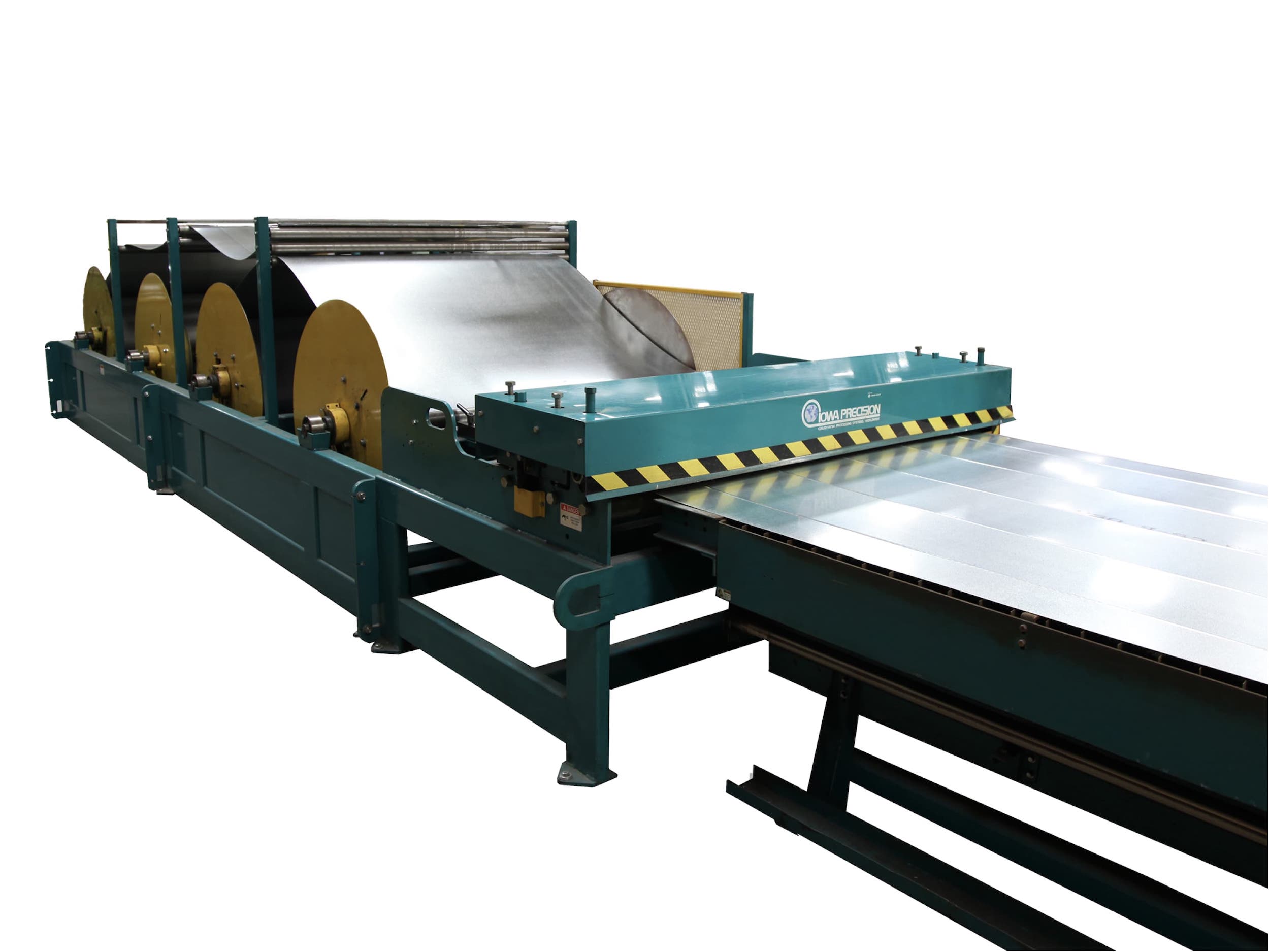

Coil Metal Processing Equipment

Insulation Cutting Equipment

Iowa Precision’s advanced coil processing technologies are field-proven and guaranteed to outperform even the most demanding expectations. Iowa Precision has distinguished itself as a world-class manufacturer of custom designed and manufactured coil processing equipment for a variety of sheet metal working industries including HVAC, roofing, and curb markets. Our range of coil processing solutions includes industry-leading coil lines, cut-to-length lines, and coil strip processors as well as the highest-quality machinery and equipment for coil slitting, coil blanking, uncoiling, coil feeding, and more. Iowa Precision’s coil processing solutions are truly the most technologically advanced and complete products manufactured in the industry today delivering the speed, production rates, and tolerances no other coil processing equipment can match and unparalleled reliability to maximize your productivity and increase product quality. For your review, below are all the machine and equipment solutions available from Iowa Precision for the commercial low-slope metal roof fabrication Industry — please don’t hesitate to reach out if you have a particular application or operational requirement that might require a customized solution… we’d love to help.

Featured Iowa Precision Machine

Schedule a 1-on-1 Consulation with an Iowa Precision Technical Advisor

For over 70 years, Iowa Precision has been the industry leader in the design and manufacturing of automated HVAC coil lines, duct fabrication systems, seam closers and corner inserters. Our wide range of field-proven solutions includes rectangular, round, and oval ductwork machinery, flexible fabrication systems, and coil processing machinery and equipment. Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with an Iowa Precision Technical Advisor today.

We're Here to Help

Have questions about Iowa Precision machinery and equipment? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs to evaluate if your project can be justified? Please don’t hesitate to reach out — we’d love to help.