- The coil is mounted on two drum collars, one being adjustable for various coil width

- Each coil drum assembly has the E-Z Load lifting system

- A hydraulic drive motor is provided for each coil station

- A manual 90° turn ball valve is used to select each motor, located at each motor

- Hydraulically powered hold down wheel for safe band removal and positive feed

- The linear support rails create a multi-grid feed system, separating the material vertically as its being used

- Coil capacity is 12,000 lbs.

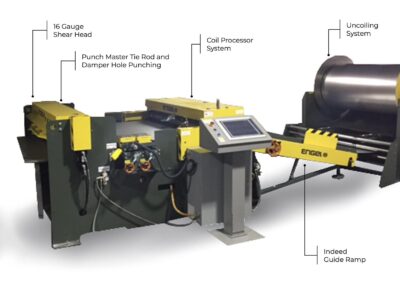

Infeed Guide Assembly — Engel’s powered underfed infeed guide assembly features include:

- Powered drive wheel to feed the material up the ramp and into the pinch rolls

- Hand wheel for easy adjustments to width variances of material

- Standard hydraulic lift for easy vertical adjustment of infeed guide

Starter Coil Line Systems — the workhorse of the industry – a fully hydraulic unitized compact coil line has earned the reputation of providing one of the most accurate and reliable machine available.

Standard features for the Engel Compact II Starter Coil Line System:

- State of the art B&R PLC based control system

- Electric servo drive motor that utilizes 4-1/4″ ground and polished rolls with heavy-duty bearings and inner races capable of removing coil set from both overfed and underfed coils

- Ring type beader with five (5) beading rings (16 ga. capacity) preset to SMACNA standards of 12-inch increments

- Notching unit includes two (2) “V” dies and two (2) “Lock” dies for use with both TDF and S/DC type duct. Each pair of dies is independently adjustable for variations in notch depth and width of material

- Twin cylinder hydraulic shear has four-sided high carbon/high chrome blades capable of shearing 16ga. mild steel

- The self-contained 10 HP hydraulic pump system is located between the solid steel side plates of the coil line.

Quick Set Die Adjustment (MM-QS) — To include air cylinders located on the “V” dies for notch depth offset from S/DC to TDF with respect to the “Lock” dies. This allows for fast notch offset by means of a toggle switch on the Compact II Coil Line.

Punchmaster Unit with Damper Hole — This unit is designed to provide tie rod holes on the center and at the ends of each leg of duct. Hole placement is programmable to meet SMACNA standards. Hole placement is entered into operator console and is automatically located through the units computerized controls for correct hole location. No manual adjustments are required.

Engel | Compact II Starter Coil Line | Features

Engel | Compact II Starter Coil Line | Testimonial: Mason Road Sheet Metal

Engel | Compact II Starter Coil Line | Testimonial: General Mechanical Contractors

Engel | Compact II Starter Coil Line | Testimonial: William H. Brady, Inc.

Engel | Compact II Starter Coil Line | Testimonial: F.G. Haggerty Fabrication