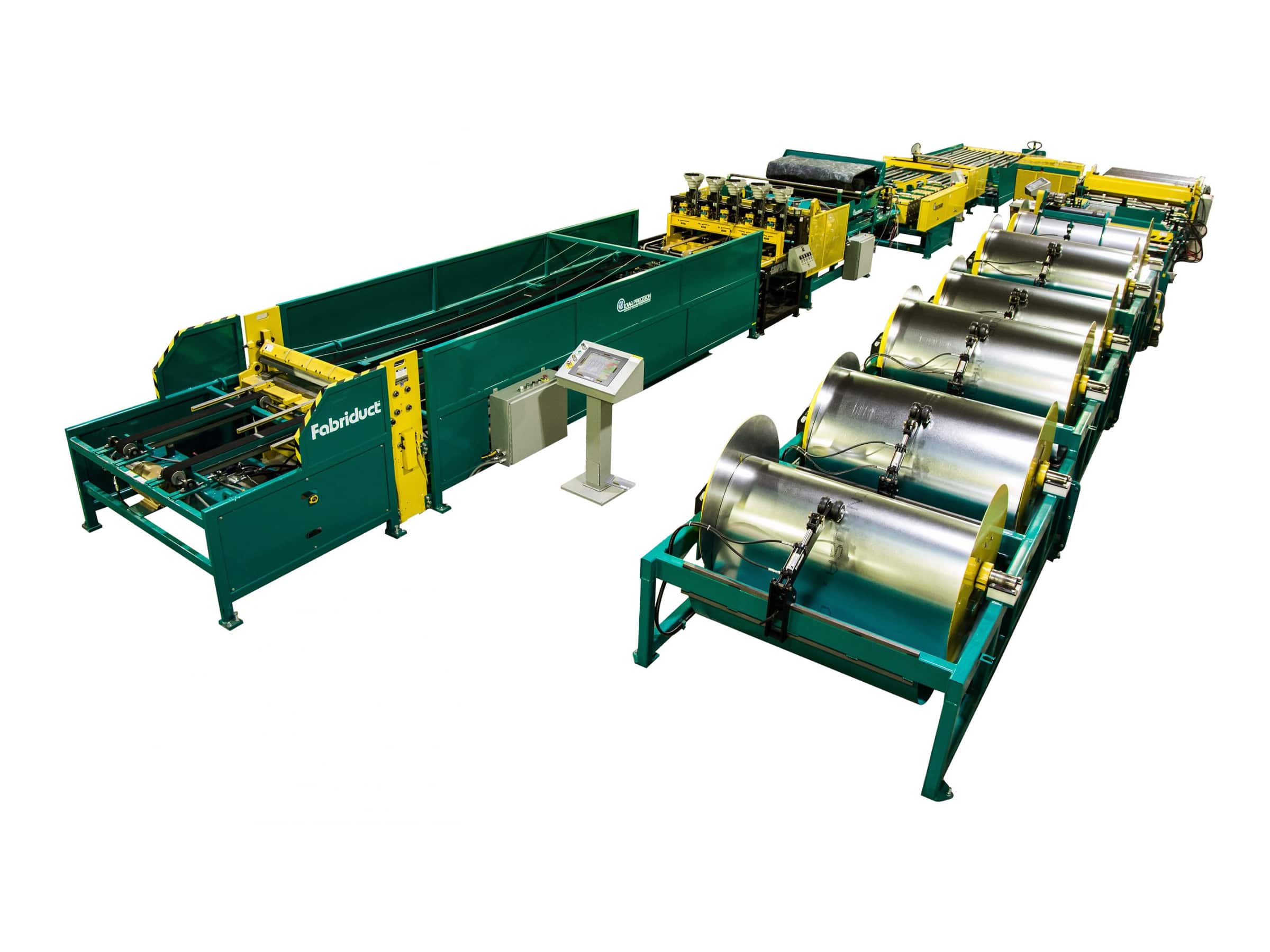

- Most economical footprint in the world and the fastest feed rate in the industry

- E-Z load coil drum assemblies for quick spool changeover (no lifting devises to add to your lift truck)

- Soft start motors for long life

- Direct hydraulically driven decoilers system on every coil station with hydraulic hold downs and low friction pockets

- Grid Skate Roll System for every coil station

- Coil Select for feeding material into the coil processor

- Industrial designed solid block die construction for a 25 year die life

- The industry’s toughest and most stable frames. Structured steel tube construction-maintaining structural strength will allow accessibility for maintenance, clean up and service.

- Full width contact feed rolls for positive accurate movement

- Engineered with heavy-duty left/right synchronization to stabilize cutting action and give the lowest moving mass, thereby reducing shock and vibration during the cutting stroke

- Quiet operating system with a sound level less than 67 DB

- Shear head squaring system designed for easy adjustment

- State-of-the-art control designed, manufactured and serviced by Iowa Precision.

- Industrial, solid-state PLC touch screen operating system controller with storage recall

- Tie Rod hole punching comes standard with both 5/16 and 7/16 punches

- Iowa Precision Swing Knife HVAC Insulation Cutting System for both fiber and non-fibrous insulation

- Solid state B & R controls with industrial quality/reliability; operator intuitive interface and graphics

- Servo driven high speed wrap brake

- Remote diagnostics and fast 24 hour service

- Inline plasma cut available

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line | New Features for Prefabrication

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line | Features

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line with In-Line Plasma Cutting | Features

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line | Features and Testimonial: Quality Heating and Air Conditioning

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line | Overhead View

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line with Lockformer In-Line Plasma Cutting | Testimonial: McGusker-Gill, Inc.

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line with CornermaticPlus and CornerMatic WhisperLoc Combination Machines | Testimonial: Mid-Atlantic Mechanical

Iowa Precision | Pro-Fabriduct HVAC Full Coil Line | Testimonial: Vision Mechanical

Iowa Precision | ProFabriduct HVAC Full Coil Line with Lockformer Inline Plasma and Waterjet | Testimonial – Gillette Air Conditioning Co.