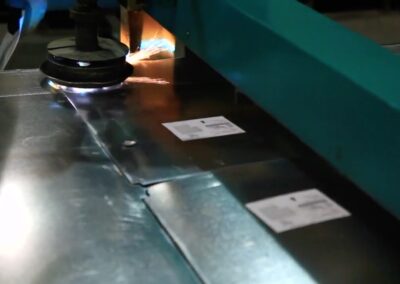

The Lockformer VulcanPlus Sheet Metal Plasma Cutting System is the benchmark in plasma cutting systems. Loaded with features for unmatched accuracy and precision, this system also has a capacity of 3/8″ and 1/2″ mild steel with a positioning speed of 3,000 IPM Max — the fastest cutting, positioning, and traversing times in the industry. The fixture-welded 3 x 3 steel tube construction ensures the frame will be as perfectly aligned today it will be years from now. The virtually indestructible plug-in components are standard and everything is protected — motors and drive systems are never exposed. Plus, the three (3) servo motors, planetary gears, and single-shaft belt are the most accurate in the industry.

Easy to Use

- Easy to identify one-piece cartridge consumables are color-coded by process to eliminate parts mix-up and simplify consumable inventory management.

- New SmartSYNC™ torches with the Hypertherm cartridge automatically set the correct amperage and operating mode, eliminating setup errors.

- End of life detection lets the operator know when it’s time to change the cartridge.

Minimizes Operating Costs

- Simplified operation minimizes downtime, troubleshooting, waste and training time.

- Advanced cartridge consumable design provides up to twice the life for hand cutting and improved quality over life in mechanized setups compared to standard consumables.

- Access cartridge data for performance tracking, analyzing usage patterns.

System features:

- All Premium “plug-in” components

- Fixture-welded, 3″ x 3″ steel tubing framework

- Stand-alone control console

- All axis home positioning using motor torque measurement

- 8” x 8” steel table leg pads with leveling feature

Drive features:

- Dual Y drive

- Double deck, 24 strand steel, precision reinforced radial timing belts

- HIWIN® linear x-axis bearing and way

- 3″ diameter x 128″ long, turned, ground and polished Y-axis guidance rail

- Precision cam followers

- X-axis brush guard

- Steel enclosed housing for X-axis servo drive motor

Hypertherm PowerMax65 Sync Plasma Cutter features:

- 50% duty cycle at 65 amp output

- Solid-state inverter power supply with output variable from 20 to 65 amps optimum performance on thickness from 28 gauge to 3/4″ metal

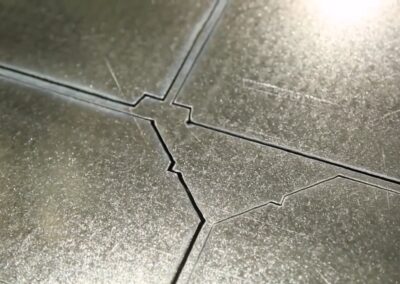

- Conical flow nozzle increases arc energy density for superior cut quality with little dross

- Patent-pending shield reduces dross buildup and enables smoother drag cutting for a better cut

- Hypertherm-shielded nozzle design to increase consumable life

- Universal power supply 220V AC single phase power supply

- CNC interface and fast-connect torch connection increases versatility

- Power-cool design cools internal components more effectively for greater system reliability and improved uptime

- Full 3 year power supply warranty and a 1-year torch warranty

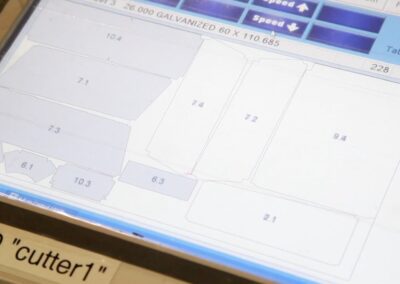

Machine control features:

- B&R Machine Controller built for demanding industrial duty applications

- Lockformer 759 CNC-TS control system with 15″ color graphic industrial touch screen

- Windows 10 VS Control software architecture

- Digital drive devices

- Manual speed increase/decrease override

- Kerf compensation

- Auto home sense to set 0/0 automatically

- Automatic corner slow down

- Brushless AC servo motors with resolver feedback

- Remote safety stop switches and current limiting drives for safety

Table features:

- 1/4″ steel plate table perimeter

- 3″ x 16 ga. CRS, multi-directional X or Y sheet support slats

- Slats can be configured for either “side-load” or “endload” of the table

- Exclusive gull-wing table design

- Rectangular exhaust plenum at the back end of the table for easy access connection

- 10″ x 12″ table exhaust ducting of 20 gauge galvanized TDC four bolt connector

- Strategically located emergency stops [1 = controller; 1 = x-axis carriage]

- 3 surface milled “L” bracket sheet stops

Software and Computer includes:

- Rectangular, drop cheek, square to round

- Round and oval complete

- Super and manual segmenting

- Automatic shape nesting and rotational nesting for minimum scrap

- Holes cutting in fittings/round/slot/square/oval

- 3-D picture preview and flat pattern layout

- Splitter vanes

- Rod re-enforcing holes cut in fitting

- Insulating cutting software

- Vulcan parts (special shape CAD program)

- Two user input station license

- Easily create and customize — color-coded labels and reports

- Microsoft Windows 10 Operating System

- Two printers

Part of the family of Lockformer Vulcan Cutting Systems which also includes: