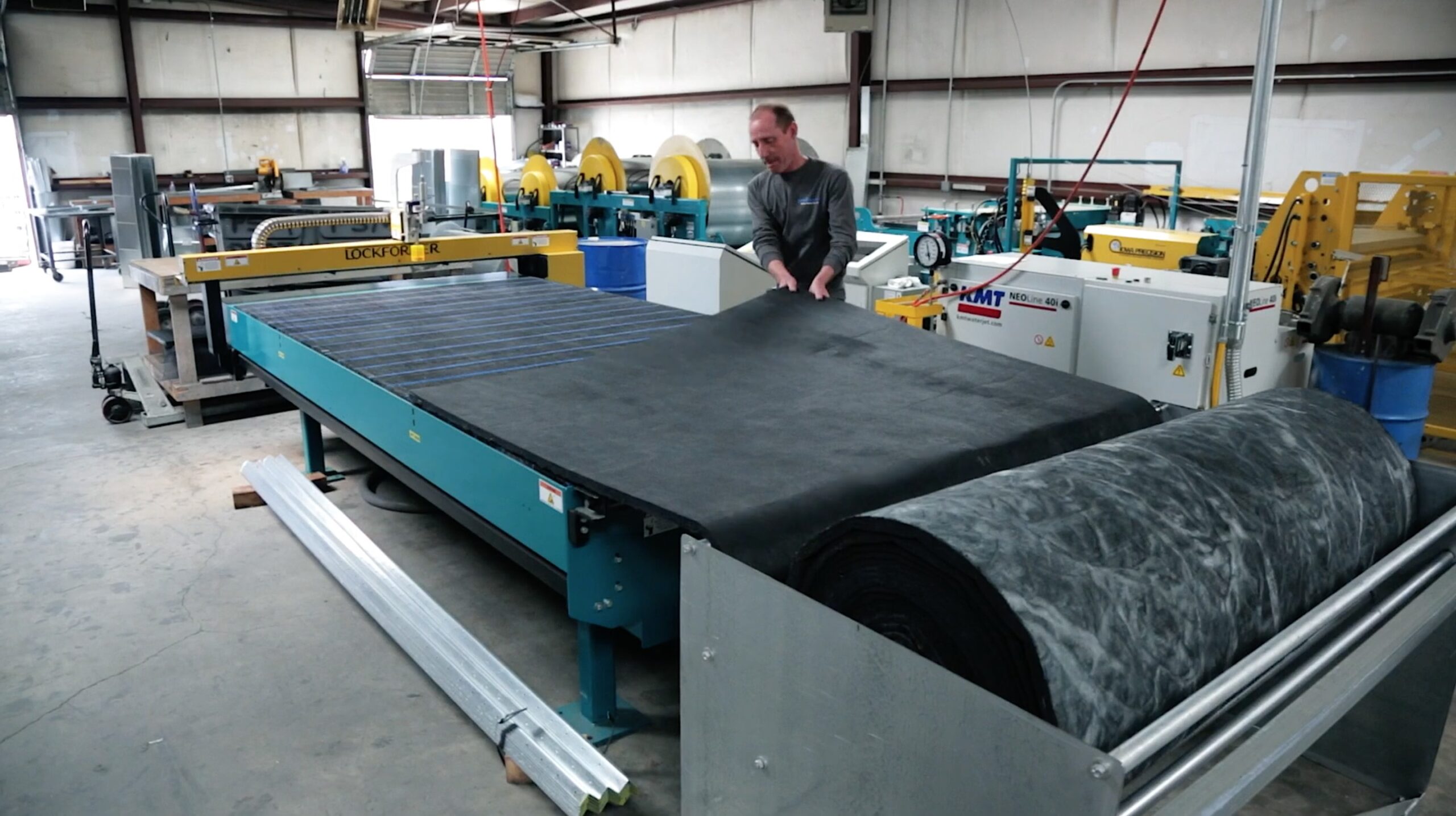

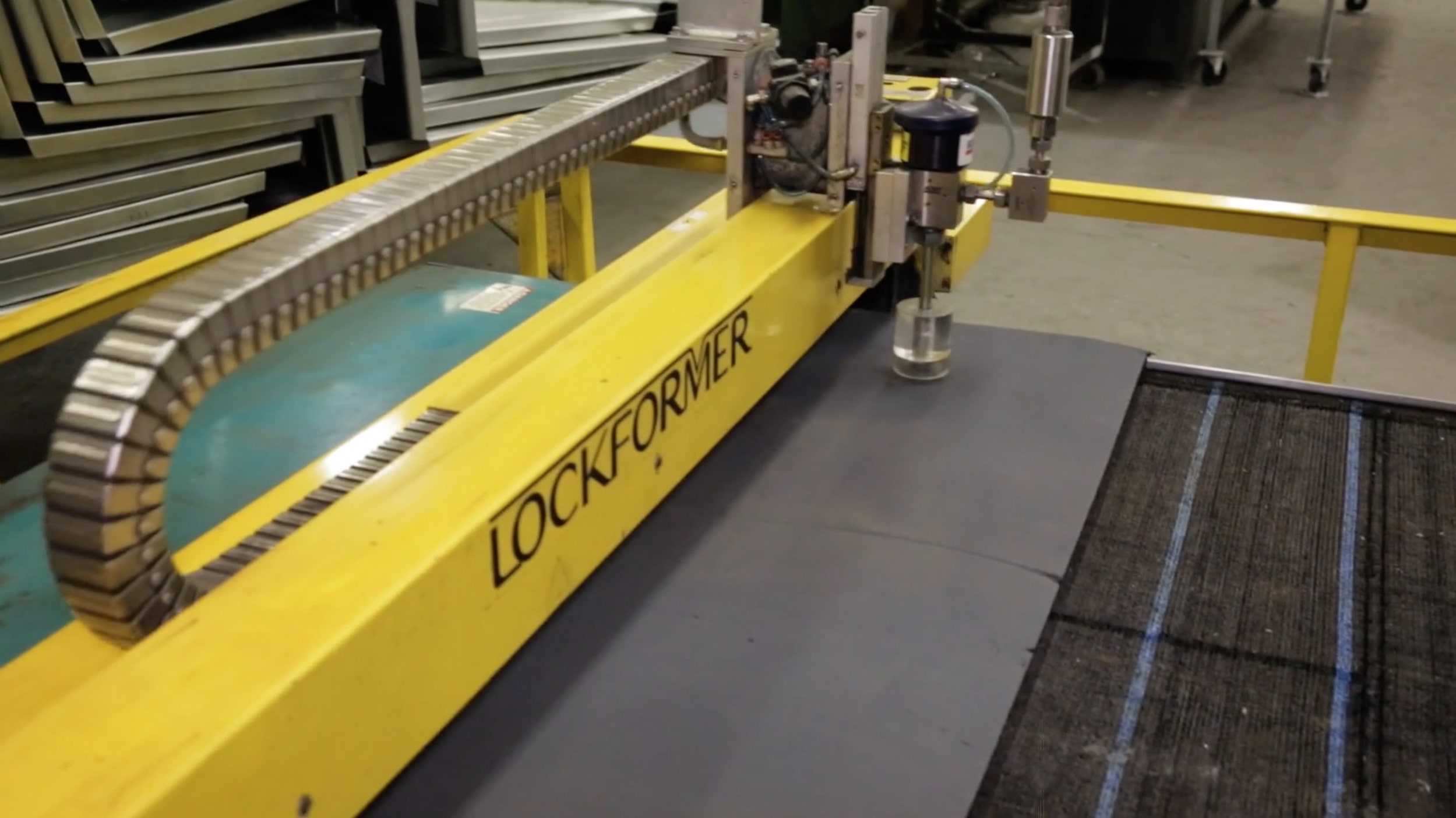

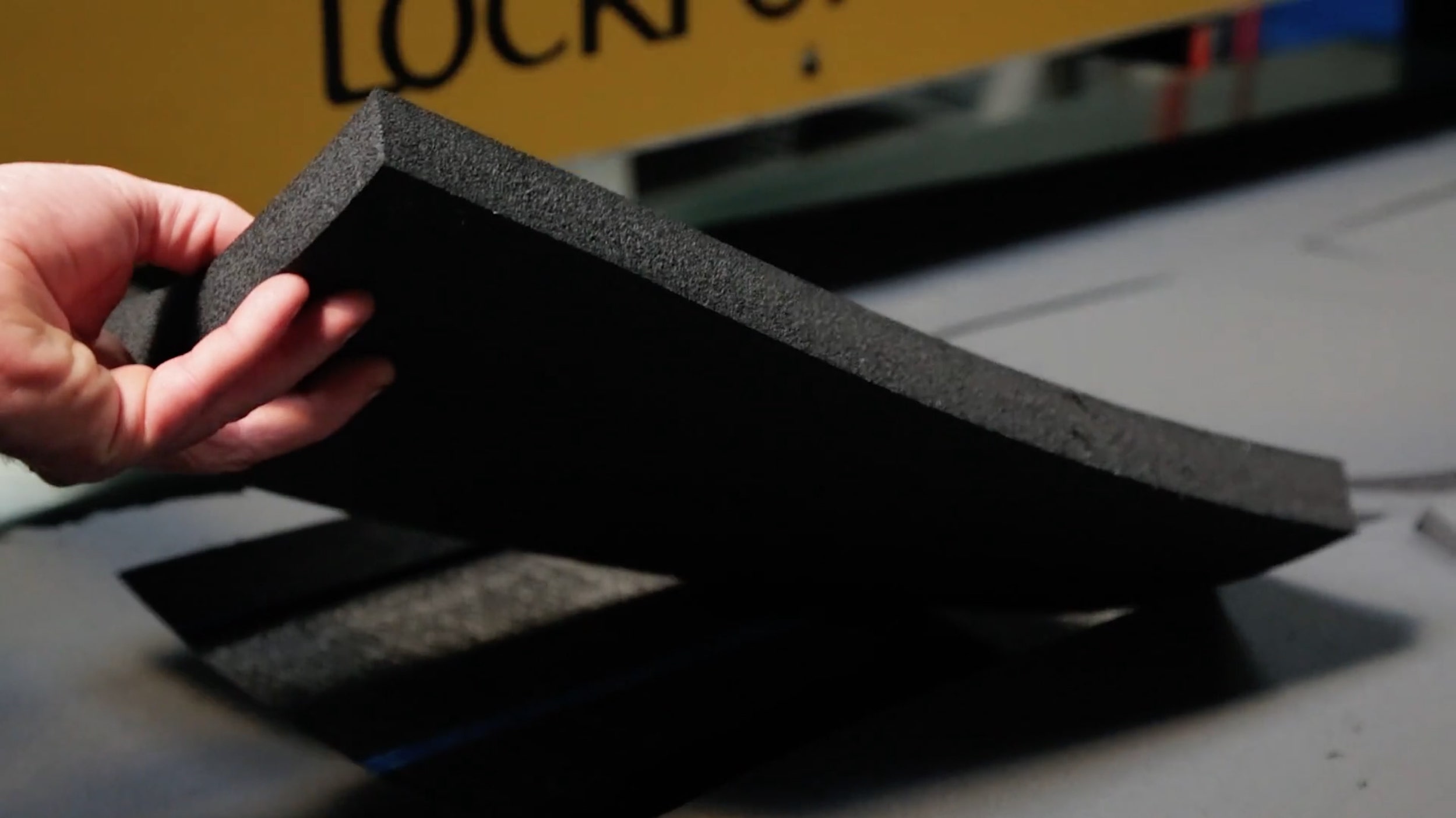

Lockformer Vulcan 1600 Fiberglass and Insulation Foam Waterjet Cutting System

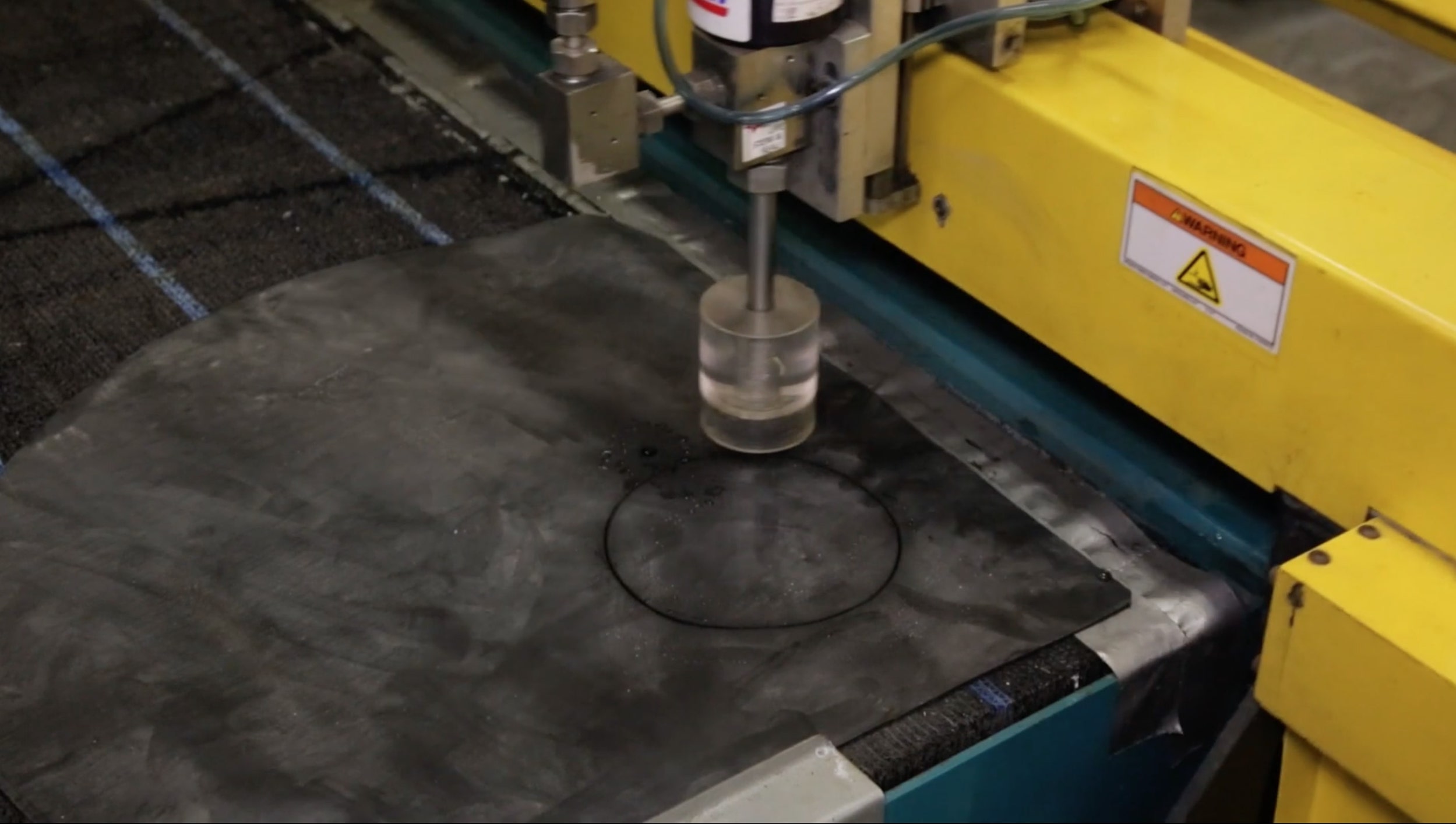

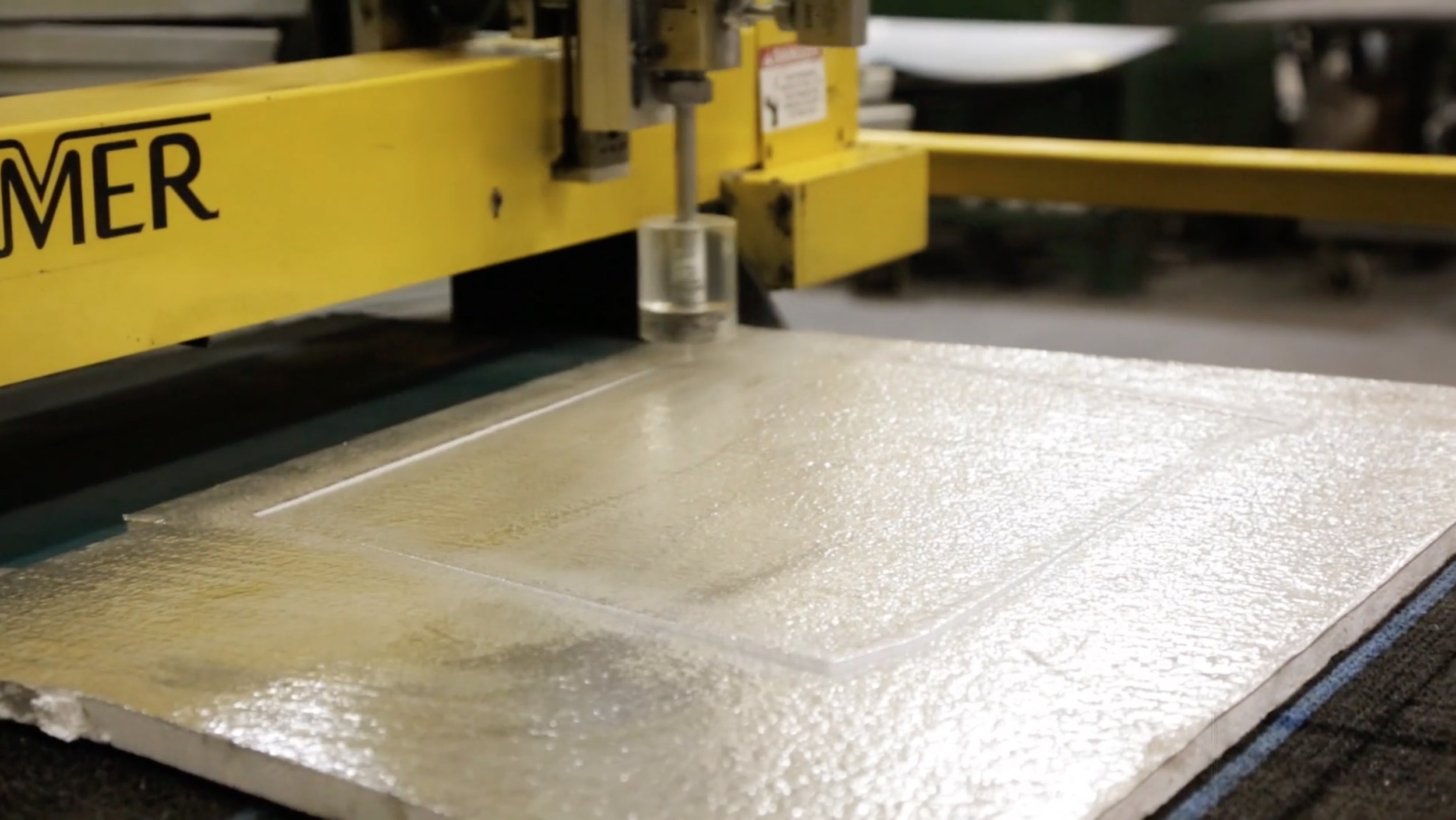

Cutting insulation manually is a slow, costly and inexact procedure. The Lockformer Vulcan 1600 Fiberglass and Insulation Foam Waterjet Cutting System automates the insulation cutting and fabrication process for mechanical contractors delivering an unrivaled level of quality and efficiency. The machine will cut up to 4″ fiberglass or 2″ foam insulation at a maximum positioning speed of 3,000 IPM. Whether you require precise insulation shapes for square to rounds, radius elbows or transitions, the Lockformer Vulcan 1600 Waterjet Cutting System can deliver savings of over 95%. With its precision speed and efficiency, the Lockformer Vulcan 1600 Waterjet Cutting System can fabricate insulation fittings for about one-tenth of what it costs to buy them or one-tenth the time it takes to cut them by hand while also reducing your scrap waste by up to 75%.

Part of the family of Lockformer Vulcan Cutting Systems which also includes:

Features

Cutting insulation manually is a slow, costly and inexact procedure. The Lockformer Vulcan 1600 Fiberglass and Insulation Foam Waterjet Cutting System automates the insulation cutting and fabrication process for mechanical contractors delivering an unrivaled level of quality and efficiency. The machine will cut up to 4″ fiberglass or 2″ foam insulation at a maximum positioning speed of 3,000 IPM. Whether you require precise insulation shapes for square to rounds, radius elbows or transitions, the Lockformer Vulcan 1600 Waterjet Cutting System can deliver savings of over 95%. With its precision speed and efficiency, the Lockformer Vulcan 1600 Waterjet Cutting System can fabricate insulation fittings for about one-tenth of what it costs to buy them or one-tenth the time it takes to cut them by hand while also reducing your scrap waste by up to 75%.

System features:

- 60″ x 120″ effective cutting area

- 60″ x 240″ optional cutting table size

- Up to 3,000 IPM cutting speed depending on the material type and thickness

- 4″ maximum cutting thickness

- +/- 1/32″ positional accuracy

- All Premium “plug-in” components

- Unitized, fixture-welded, 3″ x 3″ steel tubing framework for strength and stability

- Stand-alone control console

- All axis home positioning using motor torque measurement

- 8″ x 8″ steel table leg pads with leveling feature

Drive features:

- Dual precision Y-drive

- Double deck, 24 strand steel, precision reinforced radial timing belts

- HIWIN® linear x-axis bearing and way

- 3″ diameter x 128″ long, turned, ground and polished, heavy duty Y-axis guidance rail. Armaloy surface coated.

- Precision cam followers

- X-axis brush guard

- Steel enclosed housing for X-axis servo drive motor

- Y-axis drive housing enclosed and integral to the machine’s frame

- SNC® brand vertical dual cylinder pneumatic torch lifter with adjustable up/down pressure

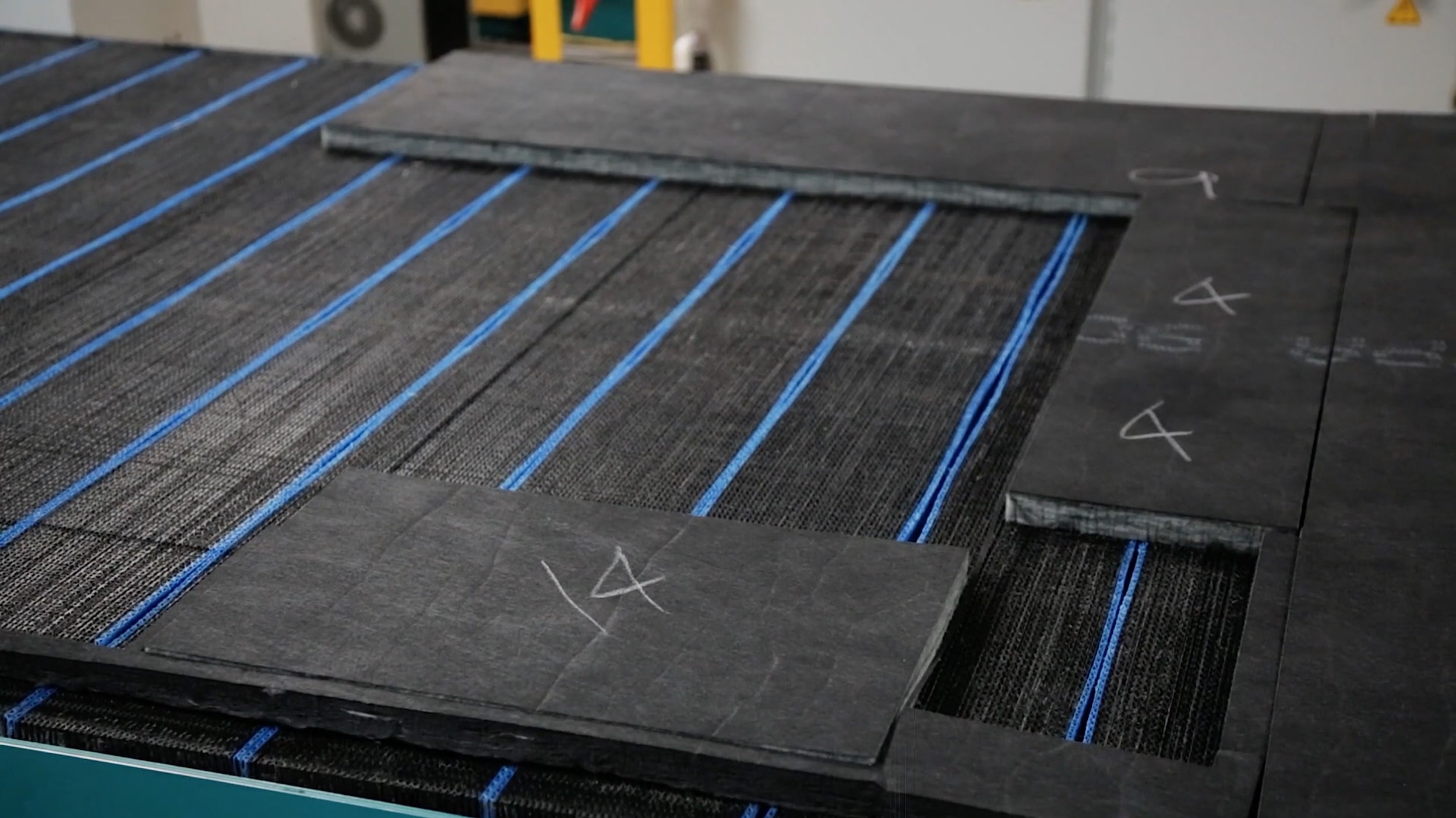

Table features:

- 1/4″ steel plate table perimeter

- “Gull Wing” table design to protect the machine’s drive system and reduce the footprint size

- Complete stainless steel table lining for rust-free performance longevity

- Rectangular exhaust plenum at the back end of the table for easy access connection

- Strategically located emergency stops [1 = controller; 1 = x-axis carriage]

Performance features:

- CPUs have the highest performance in the PLC industry

- Fastest hardware – PLCs , inverter, trigger inputs, etc.

- Complex functions are programmable in high level languages

- Scalable for quick development

- Saleable and compatible hardware

- Software can easily be adapted to different hardware configurations and machine applications

Machine Control features:

- Lockformer 759 CNC-TS control system with 15″ color graphic industrial touch screen

- Digital drive devices

- Manual speed increase/decrease override

- Kerf compensation

- Auto home sense to set 0/0 automatically

- Automatic corner slow down

- Brushless AC servo motors with resolver feedback

- Remote safety stop switches and current limiting drives for safety

Additional features:

- Superior Control: one software tool for all applications and all systems. PLC, drives, communications, operator interface, programming, and diagnostics. Robust hardware made for the industry — no moving parts, no fans, no hard disks, plus a high ambient temperature specification.

- Long-Term Availability: components made by the manufacturer, not outsourced. This enables control of components and allows Lockformer to provide components for the long haul

- Better Maintenance: central program storage to all components in the system. Field replacements without programming for servo drives, HMIs, and other components.

- Excellent Drive Diagnostic Features: ACOPOS software oscilloscope

Specifications

Model | Software / Computer System | Machine Control | Cutting / Plasma Unit | Cutting Capacity | Speed | Cutting Area and Table Capacity | Dimensions / Weight |

Lockformer Vulcan 1600 Fiberglass and Foam Insulation Water Jet Cutting System | Windows 10® Professional PC with 19" Monitor and Printer | 7590 CNC-TS and 15" Color Graphic Industrial Touch Screen | KMT STREAMLINE SL-VI 15-hp | Up to 4" fiberglass or 2" foam insulation | Positioning Speed: 3,000 IPM Max | Standard: 5' x 10' | Length: 168" |