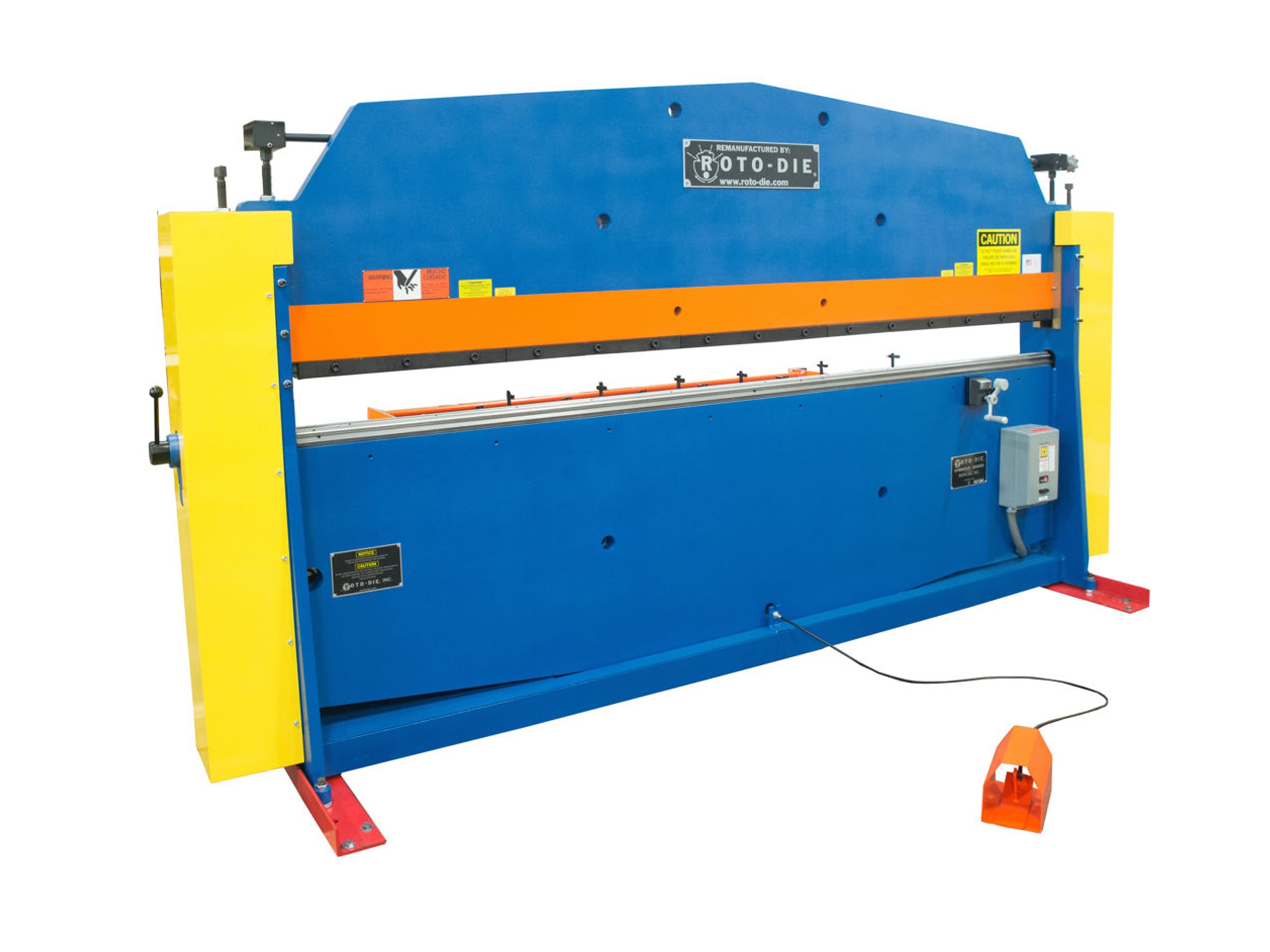

The patented Roto-Die hydraulic sheet metal benders have been a fixture in thousands of sheet metal shops for over 45 years. Here’s why:

Versatile – a Roto-Die Hydraulic Sheet Metal Brake is as simple to operate as a hand brake – but has infinitely more production capacity.

- Merely by rotating the selections lever, one operator can perform all basic sheet-metal forming operations. No dies to change.

- Forms full length ducts, gravel stops, standing lock seams, flashing and hemming operations accurately and economically.

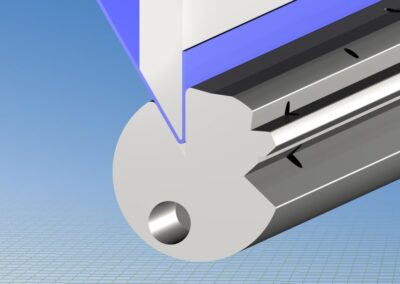

- The compactness inherent in the cylindrical die design permits acute reverse bends not possible with conventional wide-bend machines.

- Indexes quickly and accurately to all forming stations. Automatic detention assures positive die alignment.

- Centerline machined upper dies are instantly interchangeable in all Roto-Die openings without special stops or adjustments.

Productive – Most sheet metal configurations can be formed with just one handling by one operator.

- The ram may be jogged, stopped or returned to “up” position at any point of the stroke. It may also be inched for accurate positioning of the work, reducing material loss and gauge adjustment time.

- Disappearing pins are conveniently located for fast one-person positioning in cross-braking (stiffening) and rectangular duct forming. Pin gauges are easily removed and relocated.

Profitable – Roto-Die Hydraulic Press brakes are engineered to cut costs – labor costs are reduced while shop productivity is increased.

- The patented Roto-Die principle reduces setup time by as much as 70%, compared with other powerforming equipment. Gauge and clearances are adjusted more quickly than on conventional hand brakes.

- One-man operation cuts labor requirements in half on virtually all hand-brake operations.

- Simple adjustments permit operating speeds up to 50 strokes per minute for maximum production output.

- Multiple handling of sheet stock is kept to a minimum. This allows you to fabricate most commercial ventilating jobs, including the TDC duct system, in the Roto-Die in one-fourth the time ordinary benders require.

All Roto-Die Press Brake Machines include tooling for five (5) basic forming operations:

- One (1) #37 Roto-Die® with 7˚ cross-braking groove, 85˚ die opening 3/8″ wide, 85˚ die opening 7/8″ wide, 30˚ die opening 1/2″ wide

- One (1) #1 Forming Die 85˚

- One (1) #24 Hemming Die 30˚

- Six (6) sheet support arms with clips

- Six (6) #52 gauging blocks

- Six (6) #53 disappearing spring-pin gauges

Roto-Die has also developed and manufactured a number of custom dies to customer specifications which are available through special order and new dies can be made to fit your unique application. Learn more about Roto-Die Tooling and Dies

Model | Bending Capacity | Size | Speed | Motor / Voltage | Dimensions / Weight |

Model 5 | 60″ x 16 gauge | Die Clearance 2-1/8″ Die Space 7-1/2″ | Length of Stroke: 3″ Strokes / Minute: | 7-1/2 hp 3 phase, 60 Hz | Length: 7' 10-1/2" Front to back: 22" Height: 5' 3-1/2" Weight: 3,300 lbs. |

Model 10 | 120″ x 16 gauge 72″ x 10 gauge* | Die Clearance 2-1/8″ Die Space 7-1/2″ | Length of Stroke: 3″ Strokes / Minute: | 7-1/2 hp 3 phase, 60 Hz | Length: 12' 1" Front to back: 22" Height: 5' 3-1/2" Weight: 5,700 lbs. |

Model 15 | 120" x 14 gauge 120" x 16 gauge* (Stainless Steel) 120" x 10 gauge* | Die Clearance 2-1/8″ Die Space 7-1/2″ | Length of Stroke: 3″ Strokes / Minute: | 15 hp 3 phase, 60 Hz | Length: 12' 6-1/4" Front to back: 22" Height: 6' 1" Weight: 8,950 lbs. |

Model 15/12 | 144" x 16 gauge 144" x 10 gauge* | Die Clearance 2-1/8″ Die Space 7-1/2″ | Length of Stroke: 3″ Strokes / Minute: | 15 hp 3 phase, 60 Hz | Length: 14' 6" Front to back: 22" Height: 6' 1" Weight: 10,000 lbs. |

Roto-Die | Press Brake Machine

Roto-Die | Press Brake Machine | Back Gauge Options

Roto-Die | Press Brake Machine | Indexible Lower Die

Roto-Die | Press Brake Machine | Tooling & Dies