Shop Talk with Mestek Machinery is a new video and podcast series developed as way to to discuss the topics that matter most to the HVAC duct and fittings fabrication industry and to provide another good resource to fabrication shops or contractors (or anyone else in the industry) as you look for ways to improve your operations. In this episode, John Welty is joined by Mike Bailey and David Daw — two gentlemen with over a combined 80 years in the industry… icons of the industry you might say — and the discussion focuses on the software that’s used in today’s HVAC duct and fittings fabrication industry and, in particular, the data exchange for BIM modeling and how it’s evolved to be the standard of the industry today. As you’ll see in the conversation, a lot has happened from the beginnings with Computer-Aided Manufacturing (CAM) to Computer-Aided Drafting/Design (CAD) to where we are today. We hope that by discussing this evolution and how today’s software benefits so many facets of the industry, it can help you as you begin to evaluate what’s right for your operation. And don’t forget, we’re always here to help — even as you begin your evaluation. Please don’t hesitate to reach out for a consultation — we simply want to understand what you’re looking to do and see how we can help you achieve your objectives (and there’s absolutely no obligation).

Meet the Panelists

John Welty

Owner | Welty Automation

- Welty Automation is a strategic partner providing machine automation and engineering support to Mestek Machinery

-

Started at Iowa Precision Industries in 1996 on the drafting board

-

Software development progressed within engineering, and then the factory, and now the HVAC Ductline controls

Mike Bailey

Senior VP of Sales | Mestek Machinery

- 27 years in the HVAC duct and fittings fabrication and sheet metal fabrication industries

- Bachelor of Science Degree | James Madison University

- Helped develop Premier Partner Program with SMACNA

- Partner to Trimble and Applied Software Cad to Cam Processes

David Daw

President | HVAC Inventors Systemation, Inc.

- Product Development consultant to Mestek Machinery

- HVAC fabrication industry technology inventor for over 50 years

- Inventor of Cornermatic corner inserter machines, specialized TDC and TDF corners, and Bendermatic (expected to hit the market in mid-2022)

Watch the Video

Listen to the Podcast

Read the Transcript

Welcome to Shop Talk with Mestek Machinery. I’m John Welty. I’m here with David Daw and Mike Bailey, two icons of the industry, and we’re going to be talking about software in general today and a little bit of the history of how some of this equipment, and the whole business, has come together.

And so let’s kick that off to David. What have you seen being changing with how businesses are being run differently today than they were 40 years ago?

Well when I first started out, everything was manual in the beginnings of the software was on CAM, computer-aided manufacturing. That was started with very rudimentary labeling programs, which were developed by mechanical data, East Coast Sheet Metal, CTI, very early 80s.

These were programs that had somewhat of a smart label, a data attached to it where it had the cut, size, gauge metal and all a contractor had to do then or worker was manually scribe onto the sheet metal and then physically cut it with a shear or a snip and that development led to the machinery, computer machinery side where the labels where then ended up being written with code which ended up driving a plasma cut or ultimately a laser but that was actually the beginning for my knowledge. And then from that maybe the mid to late 80s the development of CAD, Computer Aided Design or Computer Aided Drafting which now allowed you the ability to sort of manually drafting a floor or an air handling unit system then you would go to a computer and that could get done so much faster but that also had data attached to it too which ultimately lead to the ability to download from a CAD drawing to a machine to both cut the fittings and to drive the straight sheet metal on a coil line basically…

There is also estimating, estimating was done all manual back in the late 70s early 80s and a couple of companies but in estimation for one in QuickPen started developing take off mechanisms with little wheels or a QuickPen that could do pin point and ended up creating an estimate that had again, smart data attached to it as far as how many pieces and gauges of metal, material, labor, cost so you could actually end up with a computerized estimate which was infinitely more accurate and faster than manual those where the two big things that happened during the 80s.

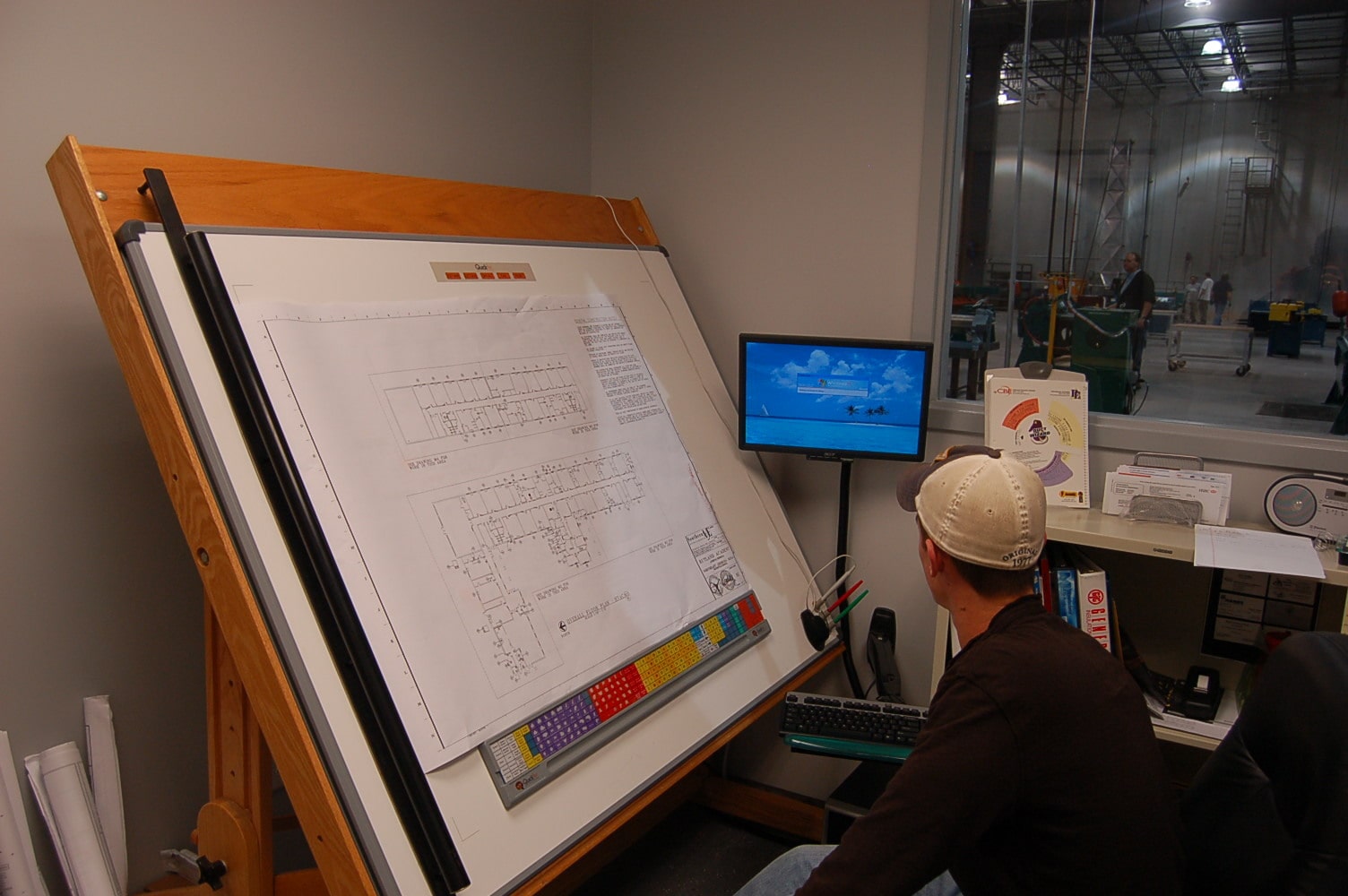

QuickPen Board and Digitizer

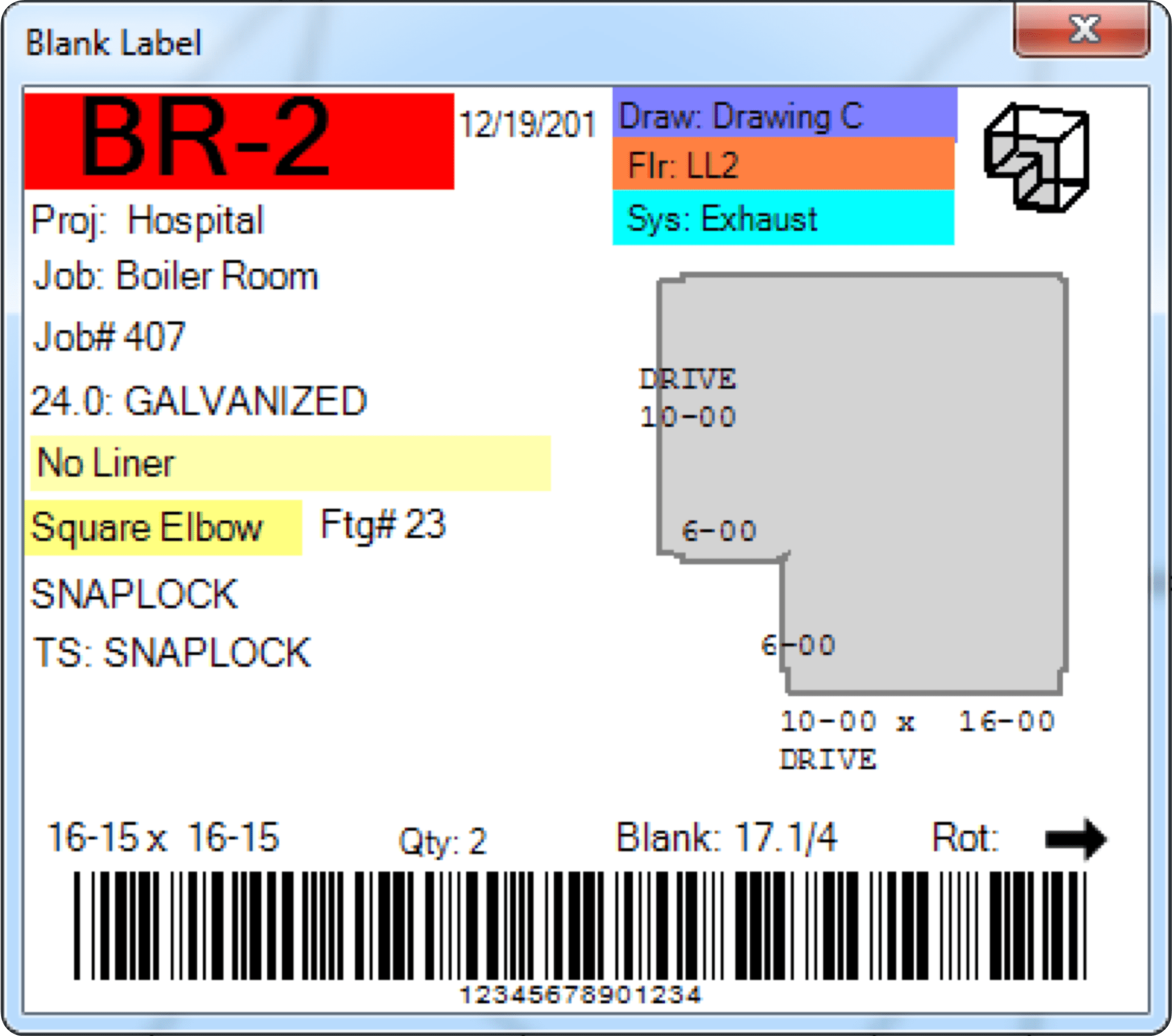

Example of Label from Trimble CAM

Yeah I don’t have 40 years of history like David does but when I came into the business in 95 the computer aided drawing was here CAM was here but it wasn’t without problem. It was with a lot of problems actually. You’re only as good as your drawings right? And they come from architects and engineers so when the computer aided drawing and shop detail drawings when they start to come out it really sped up the process because in construction today… I think we talked about it before these guys get a job on Friday they want you on site by Monday. So you got to be able to draw what they want. They use more of a Revit based program than a MEP program so that all the trades can actually draw at the same time.

And what that’s about is collision checking, to make sure that you don’t have a lot of collision between the trainees and the job. Its less input bigger output, less chance of human error that’s for sure like everything else we talked about, but the ability to do your shop detail drawings based on your specs and scopes of your shop and whoever you have to download to that camp station which then can download to the water jet, a plasma, the laser and the coil line its just created a seamless operation when it comes to getting that intelligence to the shop the manufacturer and to lessen any human error, right?

So more and more you see the contractor base going toward that technology. If you have not you should at least be curious and want to know more about it and reach out but its here the drawings are better today we do recognize that. Our detection engineers I believe heavily rely on the contractors to do this, so its helping that process as well.

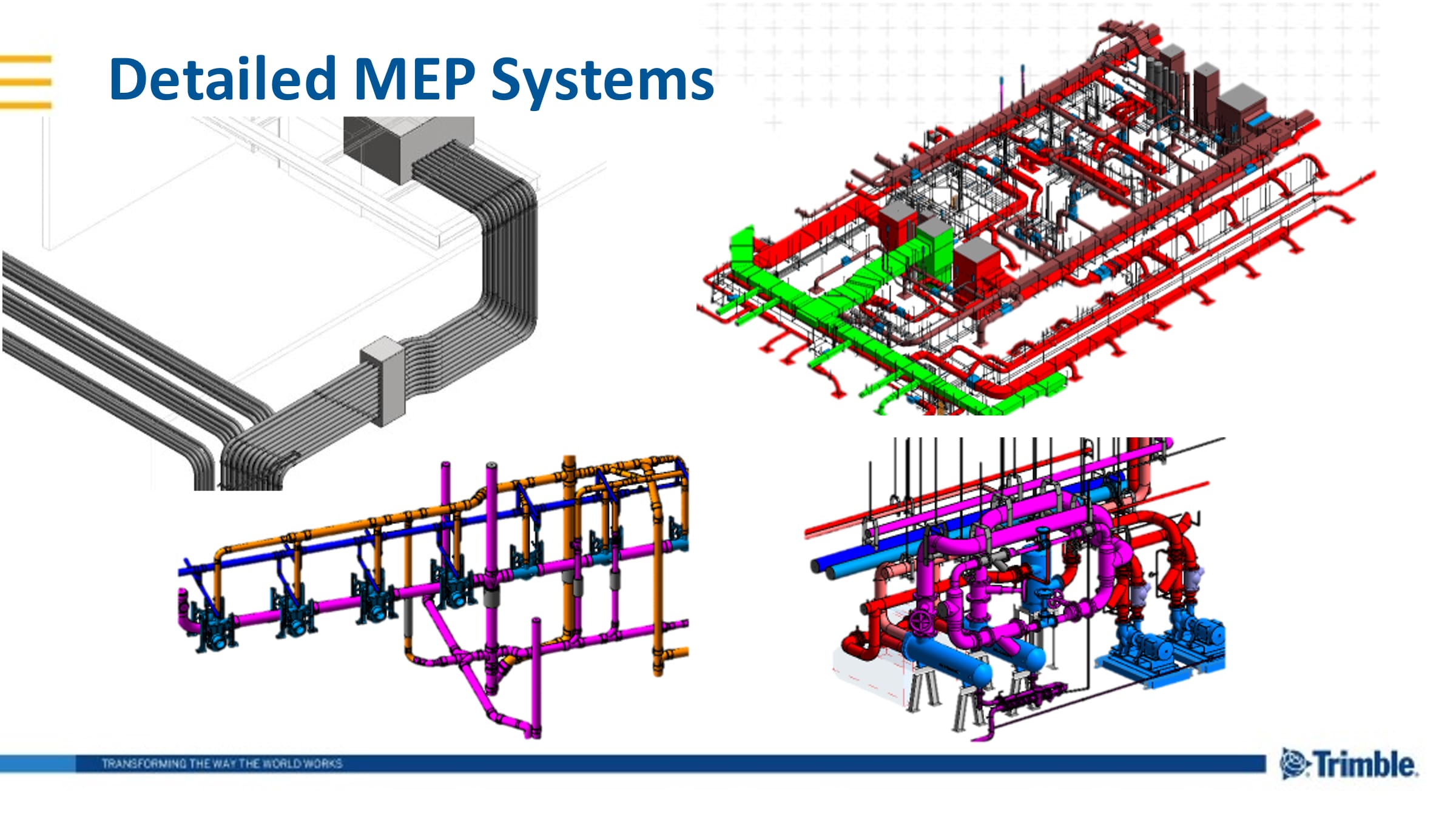

What is Building Information Modeling (BIM)?

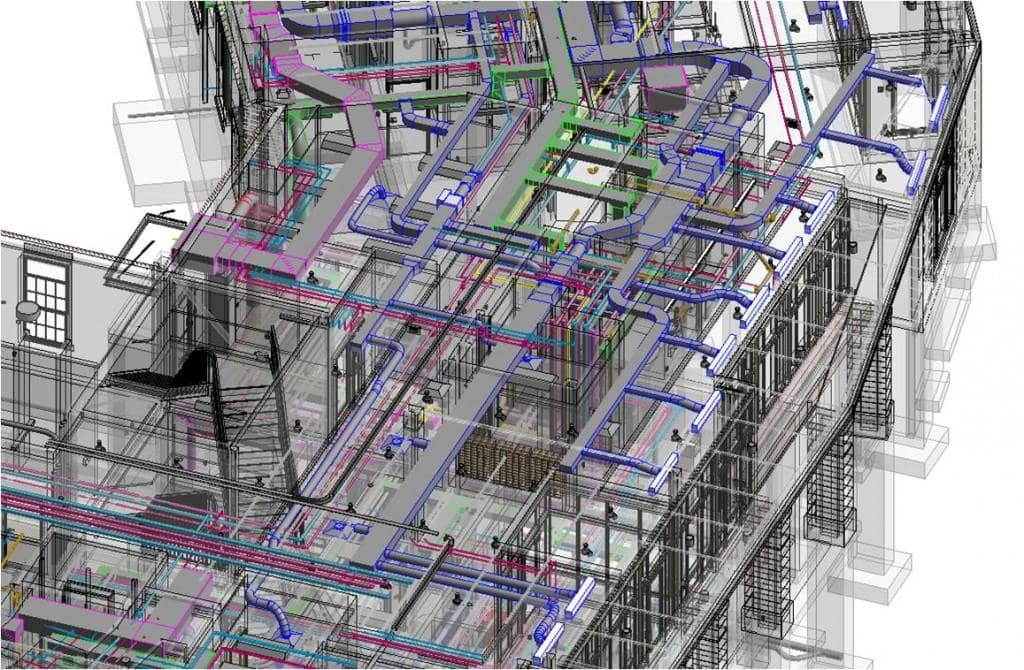

BIM is a shared knowledge resource for information on a facility forming a reliable basis for decisions during its lifecycle. The role of BIM is to gather and link data relating to the design, construction, and operation of a building to produce a comprehensive 3D model.

What is Revit?

Revit is BIM software widely used by architects, engineers, and contractors to create a unified model that all disciplines and trades can use to complete their work. Autodesk Revit was created to support BIM and not to replace BIM. Revit hosts the information that forms the model from which drawings and documents are derived.

Yeah and I know we have been involved with a lot of recent changes it seems to be something that the more we improve upon it the more we find opportunities to improve upon it further so its something that we have definitely worked on quite a bit especially once we…some of the benefits of these BIM based systems is that you now get where the contractors are wanting to cut the take outs right into the duct as its being produced in a duct line. Which created a requirement for a new protocol in order to exchange even more information down to the machine.

So I’ve been involved with some of that and working out those …defining what that protocol is and the learning what things are missing in order to help people understand what it is. How that information does have to digitally be transcribed from the way they look at it because its interesting to a contractor they are looking at these products as a finished product but to a machine producer we start with a coil of steel. They look at a piece of duct as where the sticker goes is on the outside, the bends go down and now you have a rectangular piece of duct. When you make that we actually bend it up so its upside down and we’ll have some pictures up on the YouTube video you can watch that. We’ll have some links down below so you can see some images of that. It is a fascinating thing that its kind of difficult for people to track those transitions but literally the part has to be flipped upside down and we produce it inside out and so those are all things that you just take for granted but they provide some interesting technical difficulties…

Well the reason why this is an amazing basic to the industry which particularly HVAC industry but the construction in general. Once you have a building erected in steel or in fireproofing or a concrete building you have what they call a colder building. Now you have to put things inside so you have an environmental environment that you can work in, its called the MEP, Mechanical Electrical and Plumbing and the reason why this is so difficult is, think about this, when you move water through a building or plumbing it is a fairly small round pipe. Same thing with electrical conduit but when you move air through a building you have to have a significant volume of a medium to move a square rectangular duct work around so the space inside the building is critical, but again how does this matter?

Well because if the electrical conduit or the plumbing or piping is incorrect when there is a collision with the duct work well its pretty easy to put an elbow and bend a pipe around it, but it is extremely difficult to take a say 30 inch by 40 pieces of duct work and bend it around to fit so these collisions are critical.

Now if you wanted to eliminate the whole problem you would have a building designed around the HVAC system first but that is not going to be an aesthetic building that you want to live in or work in so this is the reason why this HVAC design and collision work is so critical. The fact that you can take these mistakes out before you put the building in just saves time and a lot of money.

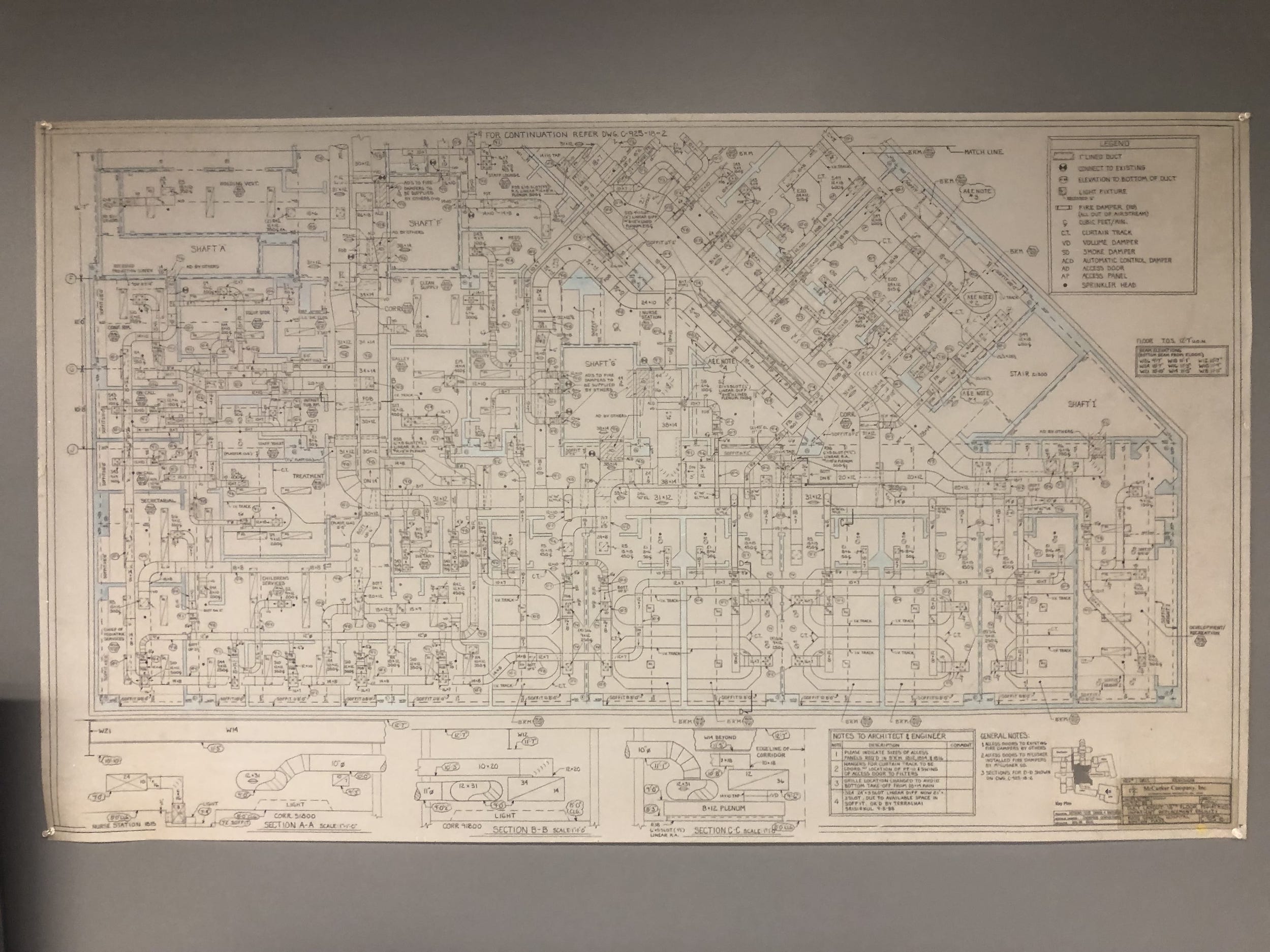

Well I guess I think the thing that comes to mind with that David is that you have some of these projects are massive. I remember one of the customers that I was assisting, that had done the new duct work for the new World Trade Center which, if you think about the volume of duct that was involved in that project its hard for me to wrap my head around, but some of those things are going to require a lot of different players to do the design work and that particular company may have done it all under one roof but a lot of them don’t, right?

So you have a lot of groups that are designing these things on separate systems and have those things not collide with one another, which is where you get into that BIM module is that they are able to do that exchange data and even though they are not on the same system or even working for the same company they can work on the same project and understand which choices have already been made by other people and let people know that we are going to need to go through here. You are going to need to remove your pipe or vise versa.

Original World Trade Center Plans – Hand Drawn

New World Trade Center Plans – Computer Drawn

Well I think that’s a good place to stop today on behalf of Mike Bailey and David Daw I’m John Welty thank you again for attending Shop Talk with Mestek Machinery join us again next time.

So hopefully our discussion of software and BIM modeling was helpful to you. Of course each shop is unique and has its own operational needs and constraints but that’s why we are here to help you as you make these evaluations on software and how to improve your operation. So please don’t hesitate to reach out for a consultation. The best place to do so is through our website at mestekmachinery.com and there is absolutely no obligation we would love to understand what you are looking to do and see how we can help you achieve your objectives. For now, thanks for listening on behalf of Mike Bailey and David Daw I’m John Welty join us again for the next episode of Shop Talk with Mestek machinery.