HVAC Round / Oval Duct and Fittings Fabrication Machinery and Equipment from Iowa Precision

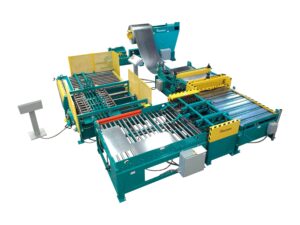

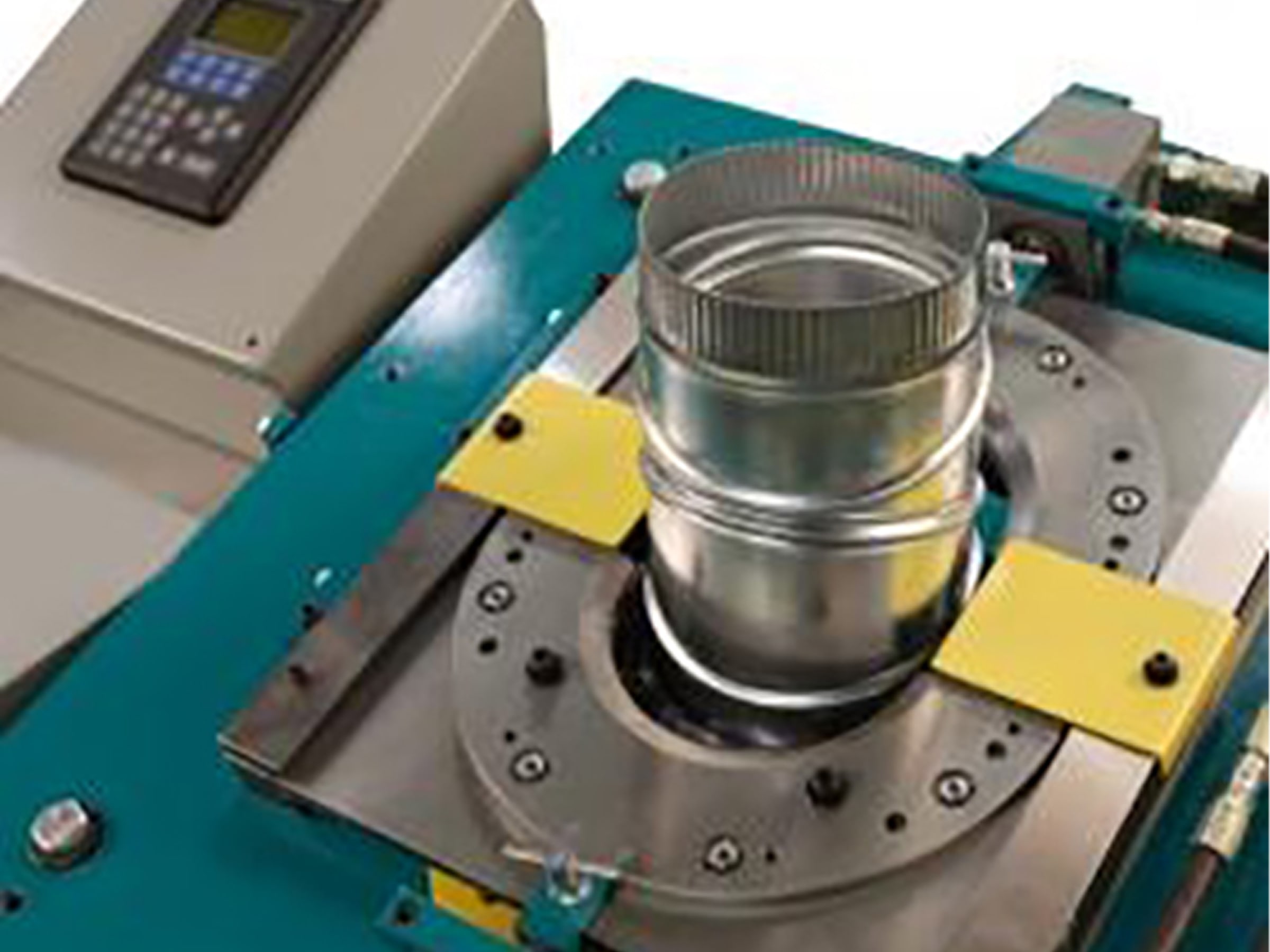

Featured Iowa Precision Machine

Schedule a 1-on-1 Consulation with an Iowa Precision Technical Advisor

For over 70 years, Iowa Precision has been the industry leader in the design and manufacturing of automated HVAC coil lines, duct fabrication systems, seam closers and corner inserters. Our wide range of field-proven solutions includes rectangular, round, and oval ductwork machinery, flexible fabrication systems, and coil processing machinery and equipment. Looking to improve the productivity and profitability of your HVAC duct and fittings fabrication operation? Looking for a solution to address a particular application? Schedule a no obligation, 1-on-1 consultation with an Iowa Precision Technical Advisor today.

We're Here to Help

Have questions about Iowa Precision machinery and equipment? Looking for help on a unique application? Need help with a budget estimate to determine overall equipment costs to evaluate if your project can be justified? Please don’t hesitate to reach out — we’d love to help.