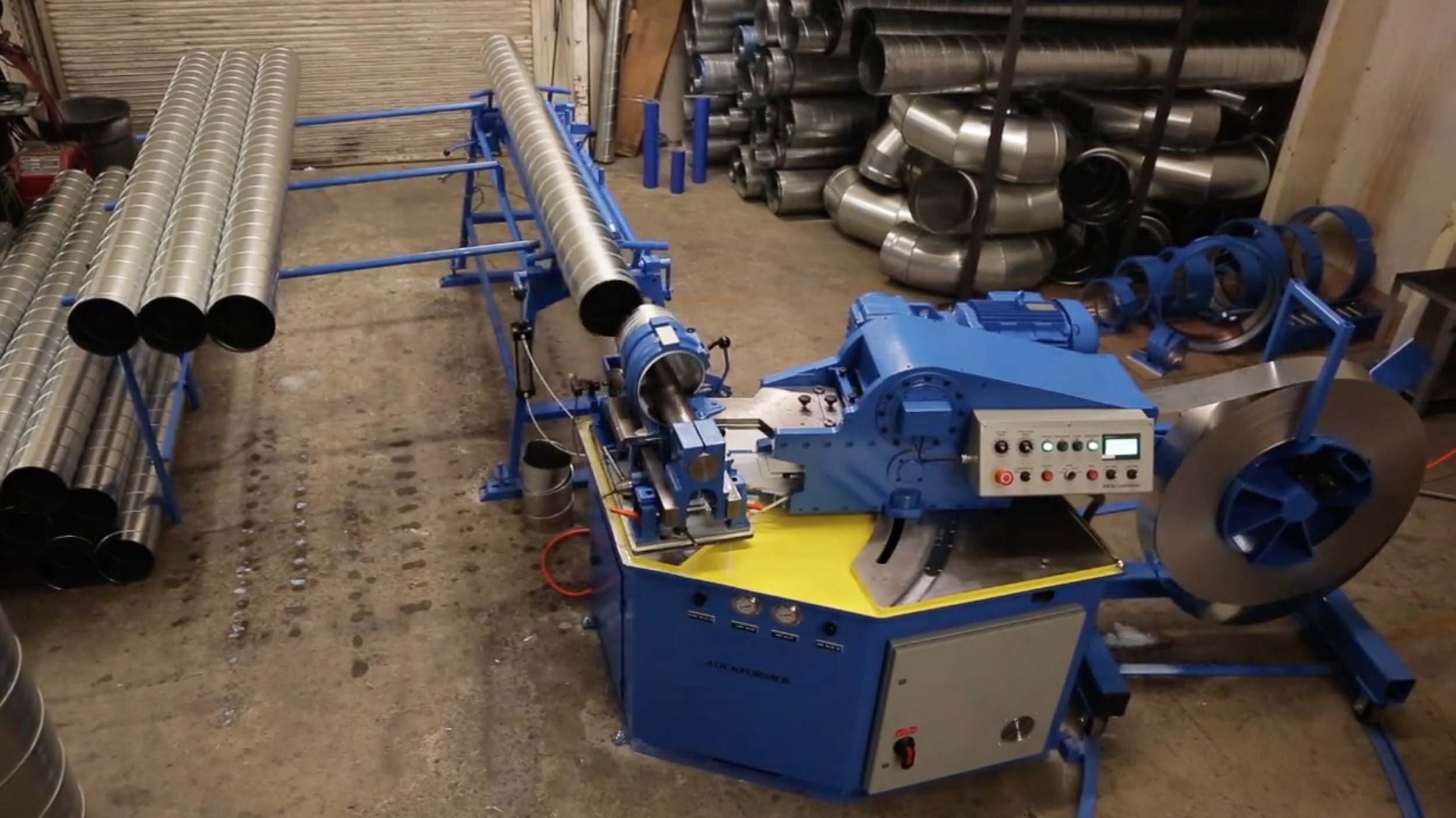

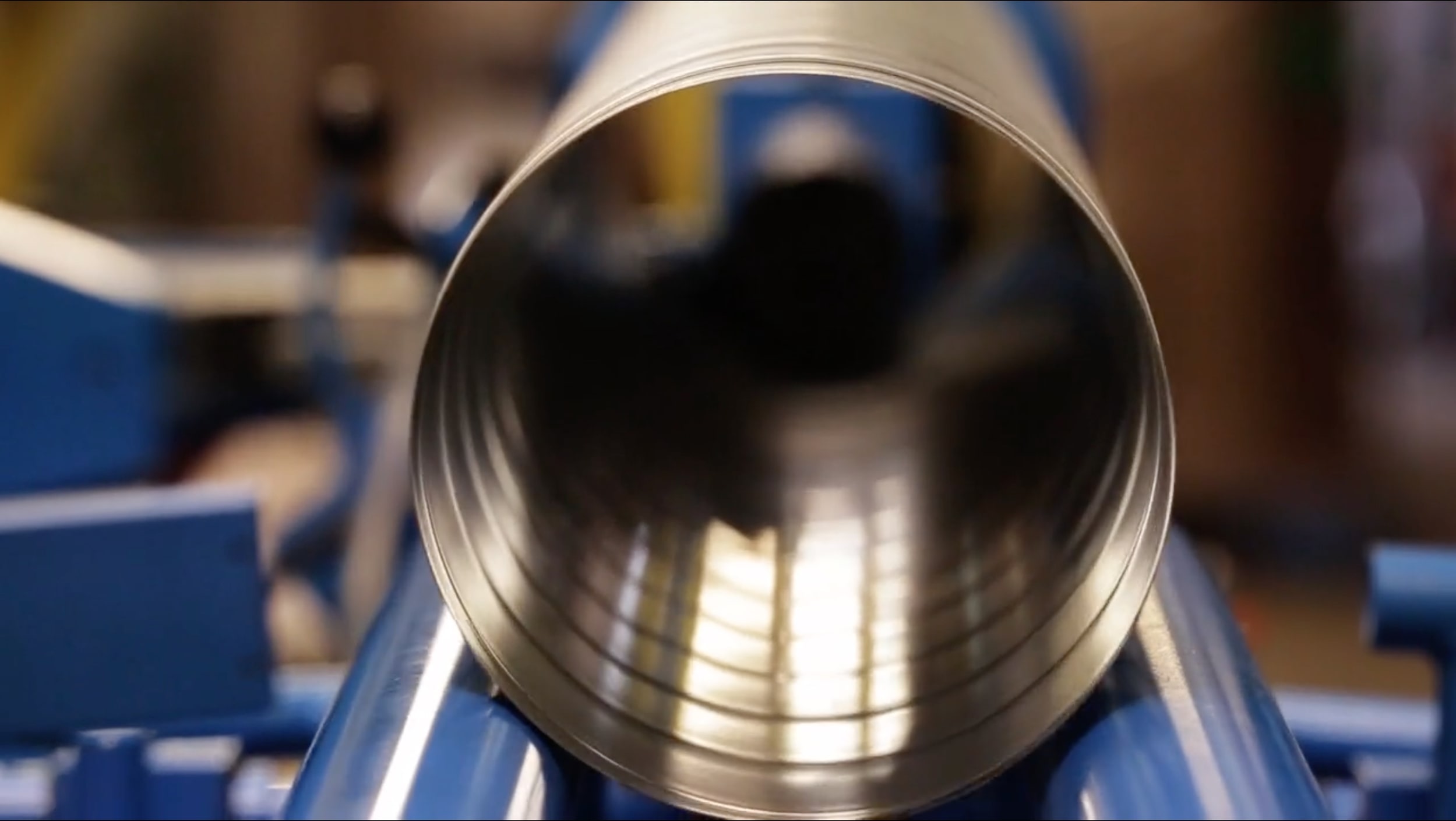

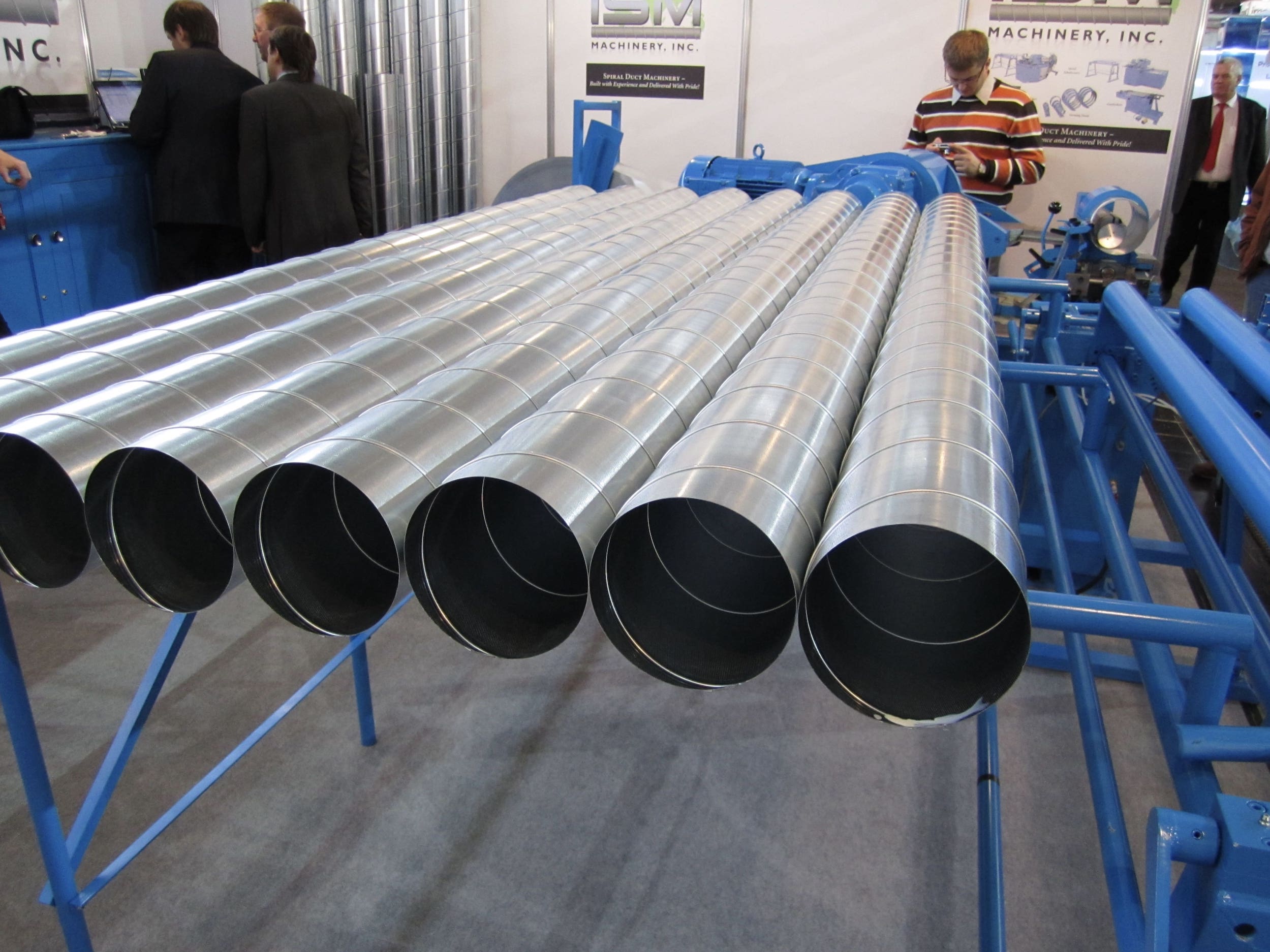

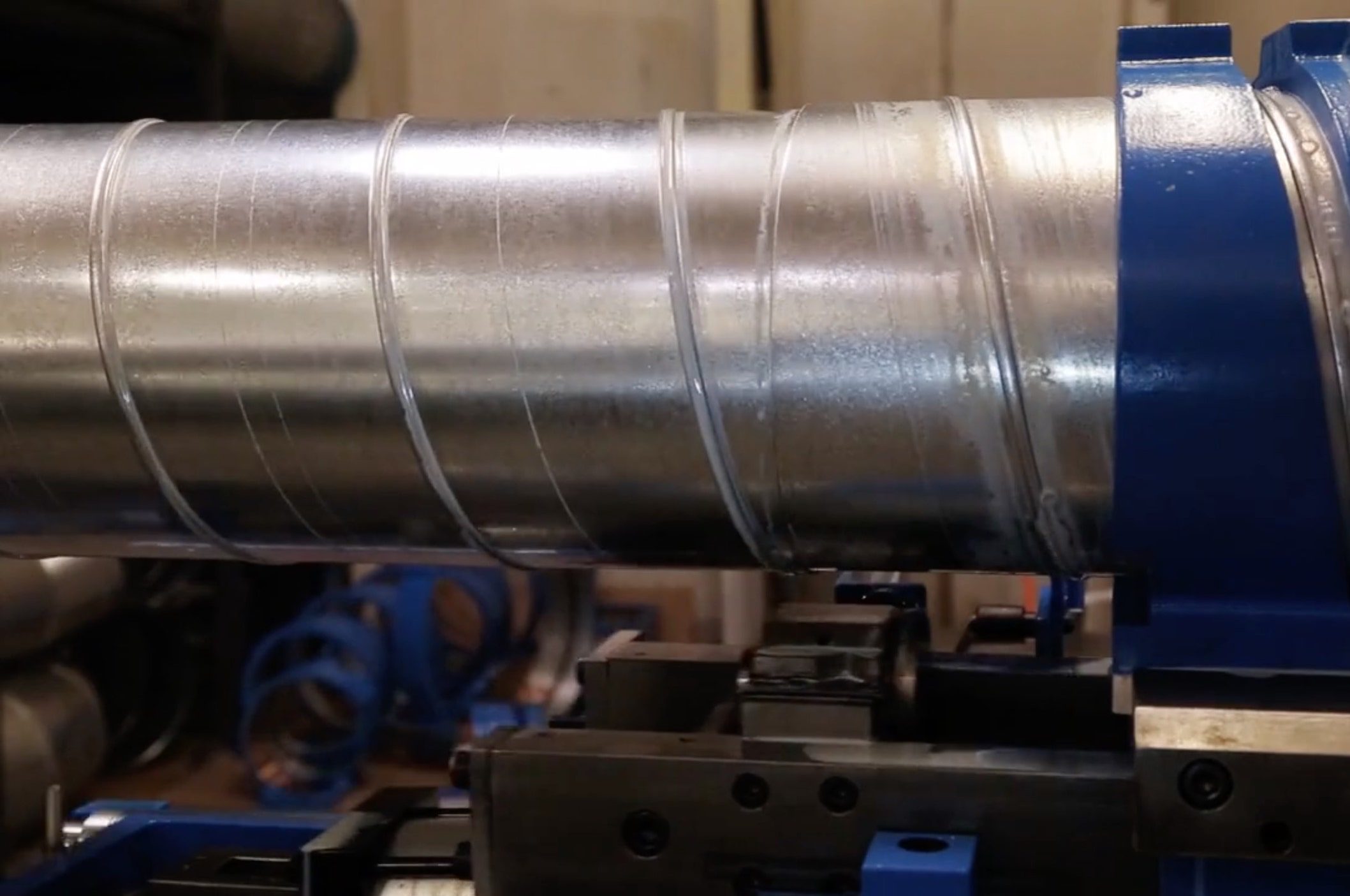

The revolutionary automatic Spiral Tubeformers from Lockformer combine the most advanced technology with one of the smallest footprints in the industry. Unlike other compact models, the Lockformer Spiral Tubeformers will not sacrifice speed, power, or technology, and are the most affordable in their class with unsurpassed features and reliability make them the best value. Available in two (2) models to meet your operational needs:

Model 1.2: Our most popular model produces spiral pipe up to 18 gauge (1.25 mm) thickness with a maximum speed of 241 ft/min (87 m/min)

Model 2.0: Our workhorse model offers both high speed and heavy gauge capacities producing spiral pipe from 28-14 gauge (0.50-2.0 mm) thickness with maximum speeds of 287-344 ft/min (84-104 m/min) depending on gauge.

Each Lockformer Spiral Tube Former is the most affordable machine in its class. Their unsurpassed features and reliability make them the best value in the industry. These features include:

- Only compact unit in the industry that is fully automatic

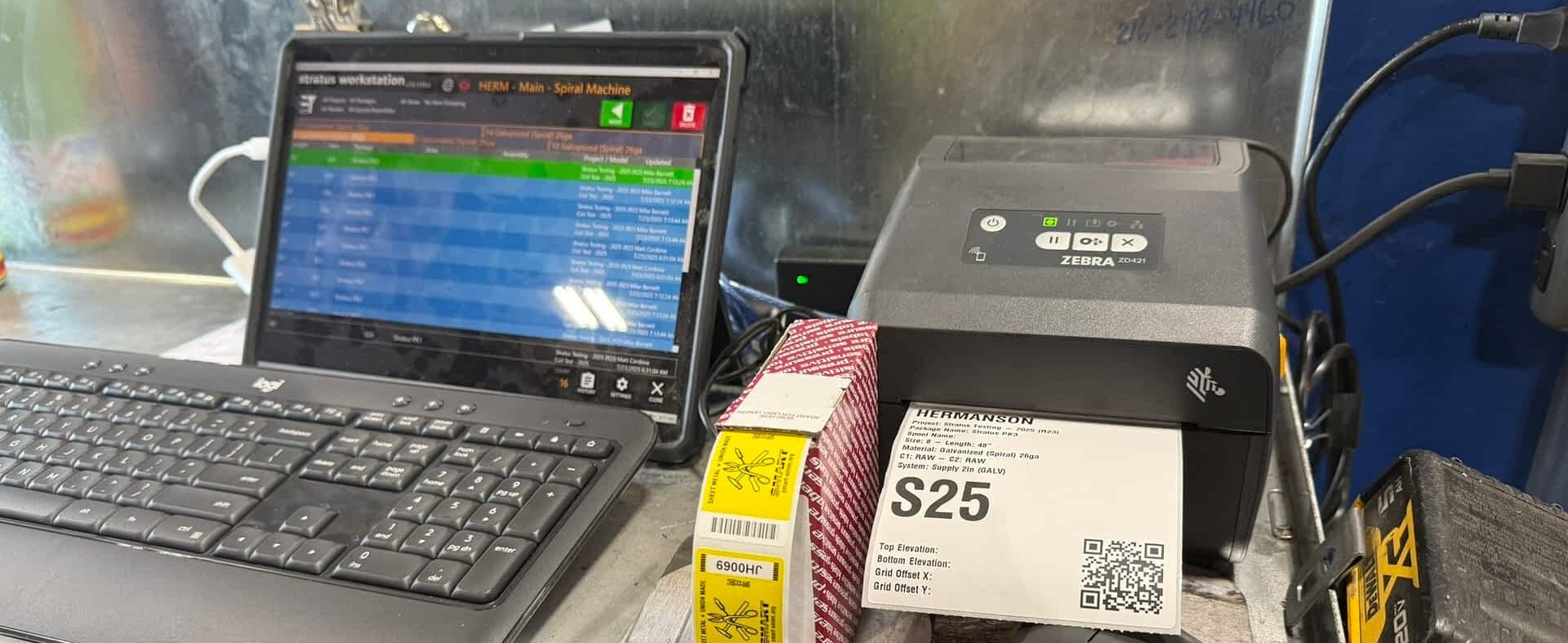

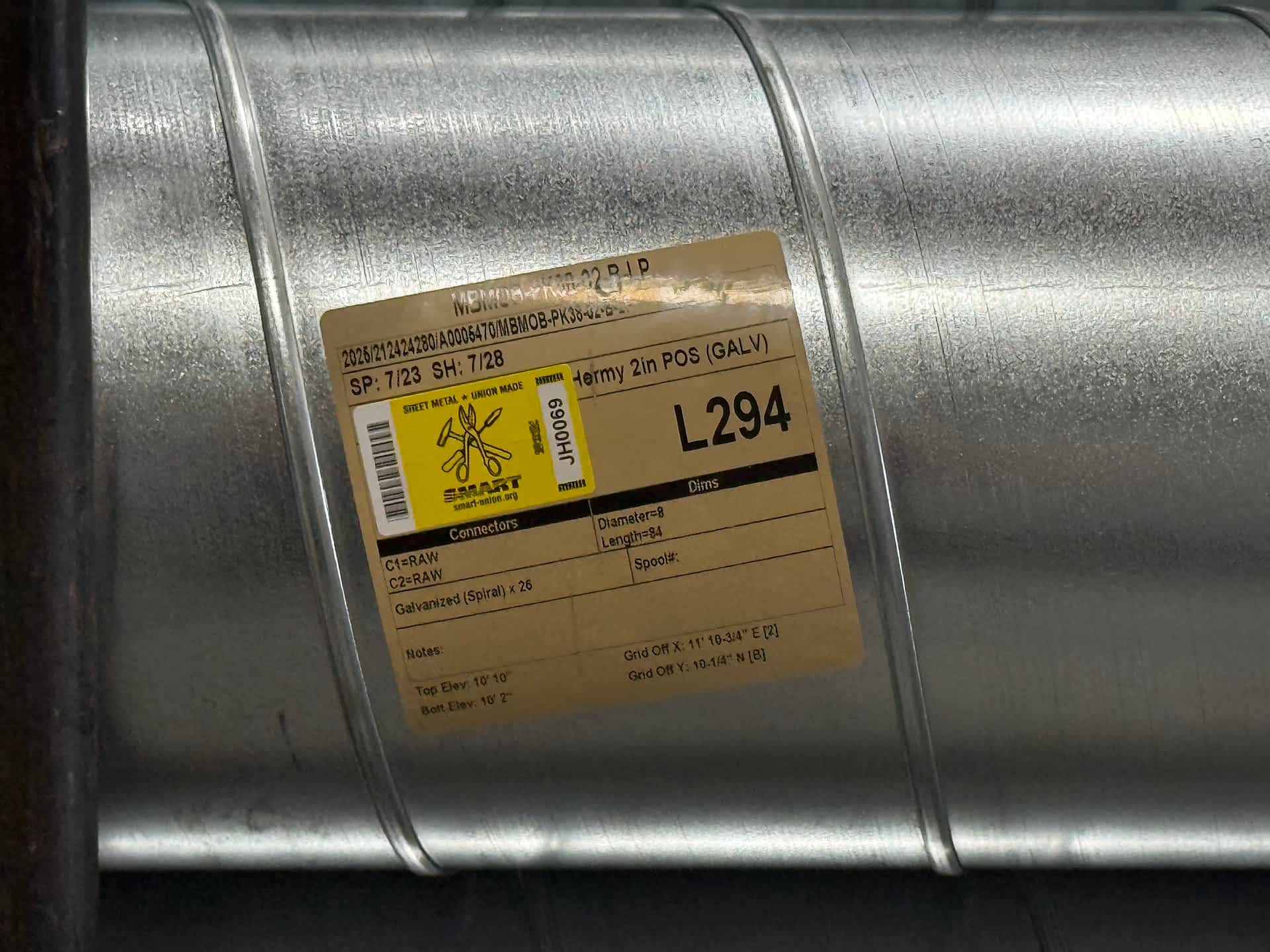

- Self-diagnostics and digital length control

- Spiral Smart Technology™, user-friendly control system takes the guess work out of set-up and pressure settings for proper operation

- On the Fly Slitting Device for silent cutting tubes of 4″ diameter and maximum material thickness of 20 gauge

- Ergonomically friendly to the operator 10’ standard run-off table

- Decoiler

- Unbeatable customer service offering technical support and parts