- Comprehensive Fitting Libraries

- Automatic Shape Nesting

- Customized Color Labels

- Accessories

- Automatic Segmenting

- Manual Segmenting

- Dampers

- Reinforcing

The CAD Providers we are currently open in architecture with are:

- Autodesk Fabrication CADmep

- Trimble SysQue

- Trimble DuctDesigner 3D

- Trimble EC-Cad

From Bid to Project Completion – You’re Covered

Hardware and software solutions are the ultimate answer for the HVAC contractor looking to tackle projects from residential to commercial while meeting tight deadlines and maintaining profitability on a project.

Vulcan Hardware & Software working Together

As an MEP Contractor, you have enough point solutions that do not talk to other solutions across your business. We understand your business and the MEP specific challenges you face. This appreciate and understanding drives our goal of connecting your design and fabrication processes for a seamless, 21st century business environment.

Estimating

Spec-driven labor and material estimating software are ideal for HVAC and sheet metal estimators. Leverage pre-built assemblies, automatic fitting generation, and integration with CAD detailing solution, estimating software is a go-to solution for large and small sheet metal contractors alike.

Fabrication

For years, Vulcan has set the bar for cutting software with the best mix of innovation and usability. At the core of its success is the unique combination of powerful, intuitive technology. Easy-to-use input screens let your operators enter duct and fittings quickly and accurately. The comprehensive fitting library within Vulcan includes thousands of fittings of all shapes and sizes which can be used in projects ranging in size from residential projects to large industrial applications, while tools such as the automatic segmenting and shape nesting tools help to drive efficiency.

Field Fitting Simplified – A Vulcan Companion

Extend the integration of design and fabrication to installation with field fitting input — providing contractors, fabricators and their installers a way to capture sheet metal fitting information in the field simply, seamlessly, and accurately.

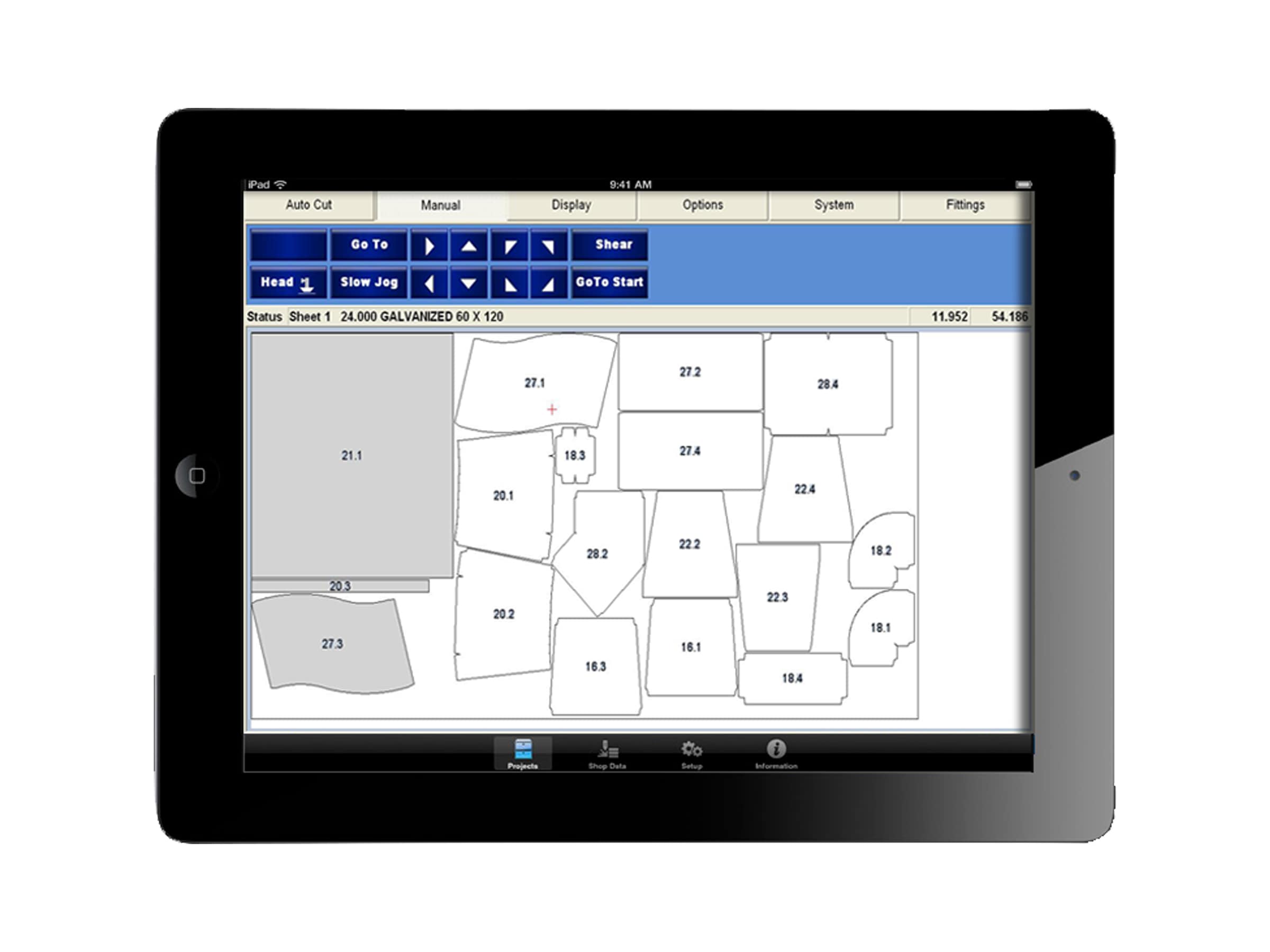

Trimble Mobile Pro for iPad

Gain additional productivity with the optional Trimble Mobile Pro for iPad, the most efficient and easiest way to enter sheet metal fitting information in the field and transfer it to the office for import into your Vulcan Cutting System CAD | CAM | MEP Software. Whether you are looking to do a small residential or large commercial project, Trimble Mobile Pro covers you with a comprehensive fitting library for most any situation. Additionally, Trimble Mobile Pro provides your organization with 97% of the Vulcan Cutting System CAD | CAM | MEP Software library of fittings. Trimble Mobile Pro allows contractors to keep each project separate, and keep floor and drawing information separate within each project. Contractors are able to enter every dimension as well as the type of metal, gauge, insulation and liner thickness, and seam data. Reduce errors and rework while increasing productivity and return on investment.

The Vulcan Cutting System CAD | CAM | MEP Software is designed to integrate seamlessly with the following Lockformer Vulcan Cutting Systems:

Lockformer VulcanPlus Sheet Metal Plasma Cutting System

The Lockformer VulcanPlus Sheet Metal Plasma Cutting System is the benchmark in plasma cutting systems. Loaded with features for unmatched accuracy and precision, this system also has a capacity of 3/8″ and 1/2″ mild steel with a positioning speed of 3,000 IPM Max — the fastest cutting, positioning, and traversing times in the industry. The fixture-welded 3″ x 3″ steel tube construction ensures the frame will be as perfectly aligned today it will be years from now. The virtually indestructible plug-in components are standard and everything is protected — motors and drive systems are never exposed. Plus, the three (3) servo motors, planetary gears, and single-shaft belt are the most accurate in the industry.

Lockformer Vulcan Fiber Laser Cutting System

The Vulcan® Fiber Laser is the next evolution in cutting systems from Lockformer. Using over 30 years of sheet metal cutting experience, we’ve designed the Lockformer Vulcan Fiber Laser Cutting System to meet the specific needs of sheet metal fabricators to help take your operation to the next level. Features cut speeds up to 1,200 inches per minute (28 m/min) on 10ga to 26ga mild steel — that’s up to 3X faster than a conventional plasma cutter and cut quality like that of a high definition plasma cutter on mild steel and stainless. Standard 5’ x 10’ zoned exhaust cutting table with an option of 5’ x 20’ produces minimal exhaust — can be sheet fed or coil fed. Exclusive patent-pending, FDA Class 1 approved open architecture design (no enclosure) provides access to parts directly from the table, eliminating the need for a pallet shuttle system.

Lockformer Vulcan 1600 Fiberglass and Foam Insulation Waterjet Cutting System

Cutting insulation manually is a slow, costly and inexact procedure. The Lockformer Vulcan 1600 Fiberglass and Insulation Foam Waterjet Cutting System automates the insulation cutting and fabrication process for mechanical contractors delivering an unrivaled level of quality and efficiency. The machine will cut up to 4″ fiberglass or 2″ foam insulation at a maximum positioning speed of 3,000 IPM. Whether you require precise insulation shapes for square to rounds, radius elbows or transitions, the Lockformer Vulcan 1600 Waterjet Cutting System can deliver savings of over 95%. With its precision speed and efficiency, the Lockformer Vulcan 1600 Waterjet Cutting System can fabricate insulation fittings for about one-tenth of what it costs to buy them or one-tenth the time it takes to cut them by hand while also reducing your scrap waste by up to 75%.

Lockformer | Vulcan Cutting System CAD • CAM • MEP Software | Testimonial: Greg Pickens — ADJ Sheetmetal, Inc.