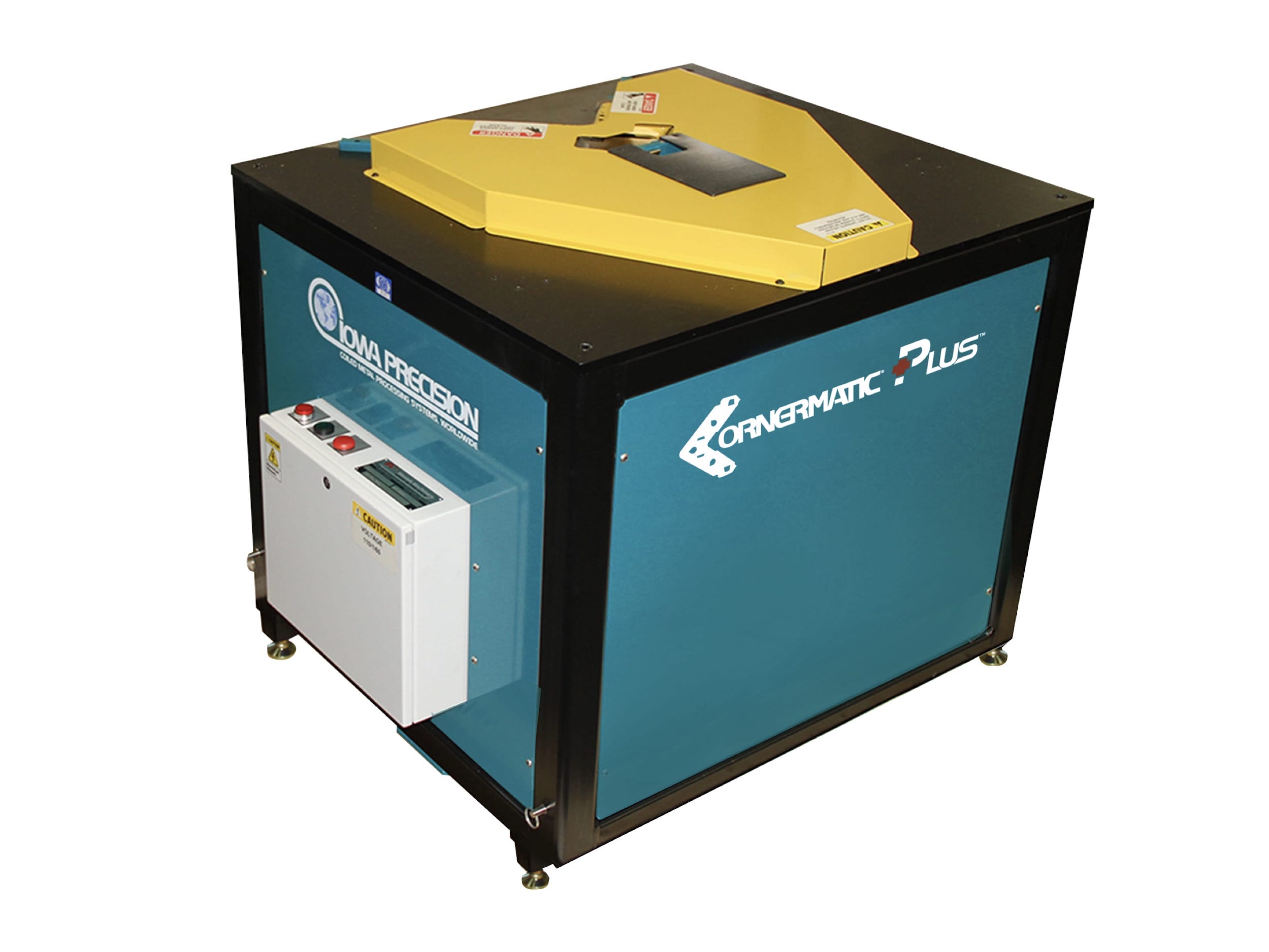

Features of the Iowa Precision Cornermatic Plus HVAC Ductwork Corner Insertion Machine:

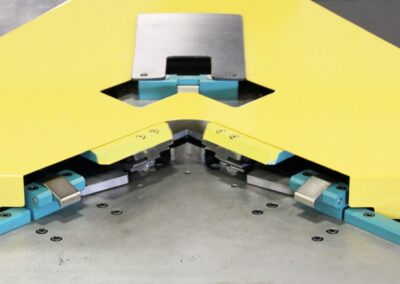

- Specifically designed for the fabrication of duct fittings — even the toughest inside or outside angle off-set transition fitting from 16-26 gauge

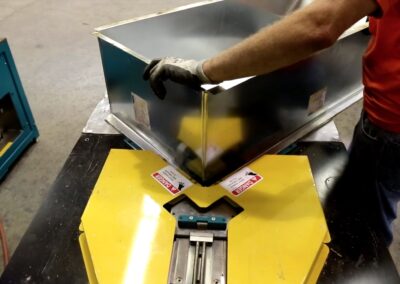

- Fully automated – no switches or foot pedals – just push in and Cornermatic Plus does the rest

- Completes eight (8) corner inserts in seconds

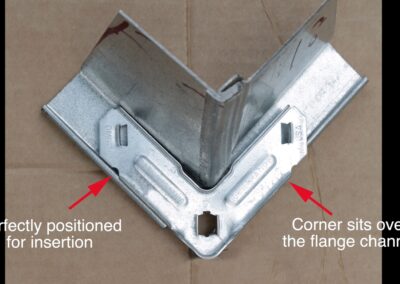

- New quick loading StrapPak™ packaging technology speeds loading and eliminates the need to sort and orient the corners before installation

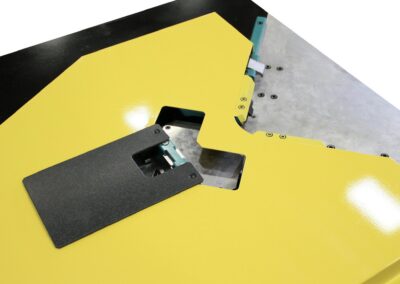

- Corners feed from below the work-surface allowing a clean, unobstructed work area

- Handles tight square throat elbows and flex connectors

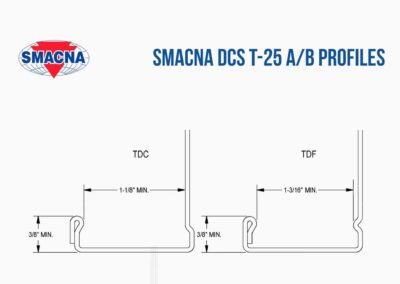

- Works with SMACNA-conforming, T-25a and T-25b flange and many other flanged duct systems without changing settings

- Ask about optional table or ‘in-floor’ mounted unit

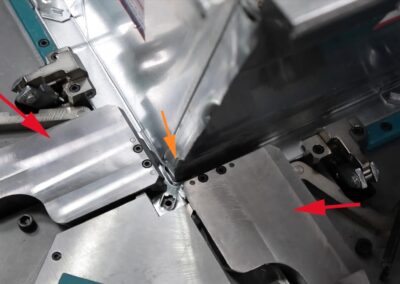

- Corners are inserted square and fully crimped

- No need to change the crimping adjustment when inserting corners in 16 to 26 gauge ducts

- Each quick loading box holds 80 corners-loads in ten (10) seconds

- Corners are shipped presorted and oriented for direct loading into the magazine

- Adjustable legs to match most bench heights

- Handles particularly difficult inside angles on off-set transitions with a breeze

- Easily handles tight square throats

- Will do odd size fittings such as flex connectors and curbs

Model Capacity Depth of Pocket Other Speed Motor / Voltage Dimensions / Weight Model Capacity - Max 80 Corners StrapPak™ Quick-loading sleeve loads in 10 seconds Length: 32" Weight: 600 lbs.

Mild Steel Only

Air - 85 to 100 PSI (5.5 - 7 Bar)

Width: 36"

Height: 34"

Iowa Precision | Improving the Shop Floor Layout of your HVAC Duct and Fittings Fabrication Operation for Maximum Productivity | Preview

Iowa Precision | Improving the Shop Floor Layout of your HVAC Duct and Fittings Fabrication Operation for Maximum Productivity | Registration Required

Iowa Precision | Cornermatic Plus HVAC Ductwork Corner Inserter Machine | Features & Tutorial