David:

Somewhere in then, and then things started to change.

Mike:

That was primarily 48 inch wide.

David:

It was all 48. Because when I first started in traveling to Grittendale in ’70, ’69, ’70, most of it was four foot metal. In fact, I was in a garage at Cedar Sinai’s Hospital-

John:

So you’re talking about a four foot wide cool?

David:

Four. Yeah. Well, for the length of duct. I was in Cedar Sinai’s garage here about two weeks ago, and it was four foot duct. I mean, it was just really interesting. And so, you can almost date when this building was built by that. But it was mostly 48, and the switch to five foot coil started around 1970, give or take.

John:

And so, a lot of shops started up with just handling sheets first. I mean, even today, some small shops will start off with handling sheets, because that’s the entry level of the equipment and the investment, the capital investment.

Mike:

Sure. Yeah.

John:

And then, at what point does it progress? That’s where you see on … When we talk about innovation over time, coil line didn’t even exist prior to that point in time, but then it still became an option as a company was growing. So it’s not just innovation in the industry, it was also innovation for a company, each of the customers, right?

David:

Yeah. [crosstalk 00:04:56]. The biggest innovation was

Engel Shopmaster, somewhere in the 1950s. Every contractor in the world had that. Now, at that point in time, Engel was a standalone company, now part of our family. But the Shopmaster was the machine prior coil.

John:

That pulled metal off of a coil?

David:

No. Just sheet stock. [crosstalk 00:05:16]-

John:

Oh, that was sheet also?

Mike:

It would not. It would shear. It was all sheets. It was all manual.

David:

Manual.

John:

Oh, okay.

Mike:

I believe that was a Herb Fisher design, going back that late, maybe now?

David:

It could’ve been … What was … Engel. Herb may have been involved, but Engel, and I forgot the guy’s name who started Engel, something Engel, he was the one that I believe was it Ed, but it could’ve been Herb.

Mike:

But it seems like the history I’ve been told, that’s what developed into the coil. It was the Shopmaster, then the coil line.

David:

Correct.

John:

And the coil line, in that early day, was much different than what it is today. Right? They didn’t do any insulation.

Mike:

Correct. Not in the beginning.

John:

There wasn’t pinning at the early time?

Mike:

No.

John:

Did it start as just punching and notching from a coil and stop there?

Mike:

Yeah, just need to stop so you can test the link.

John:

So it’s just what they call, a starter line today?

Mike:

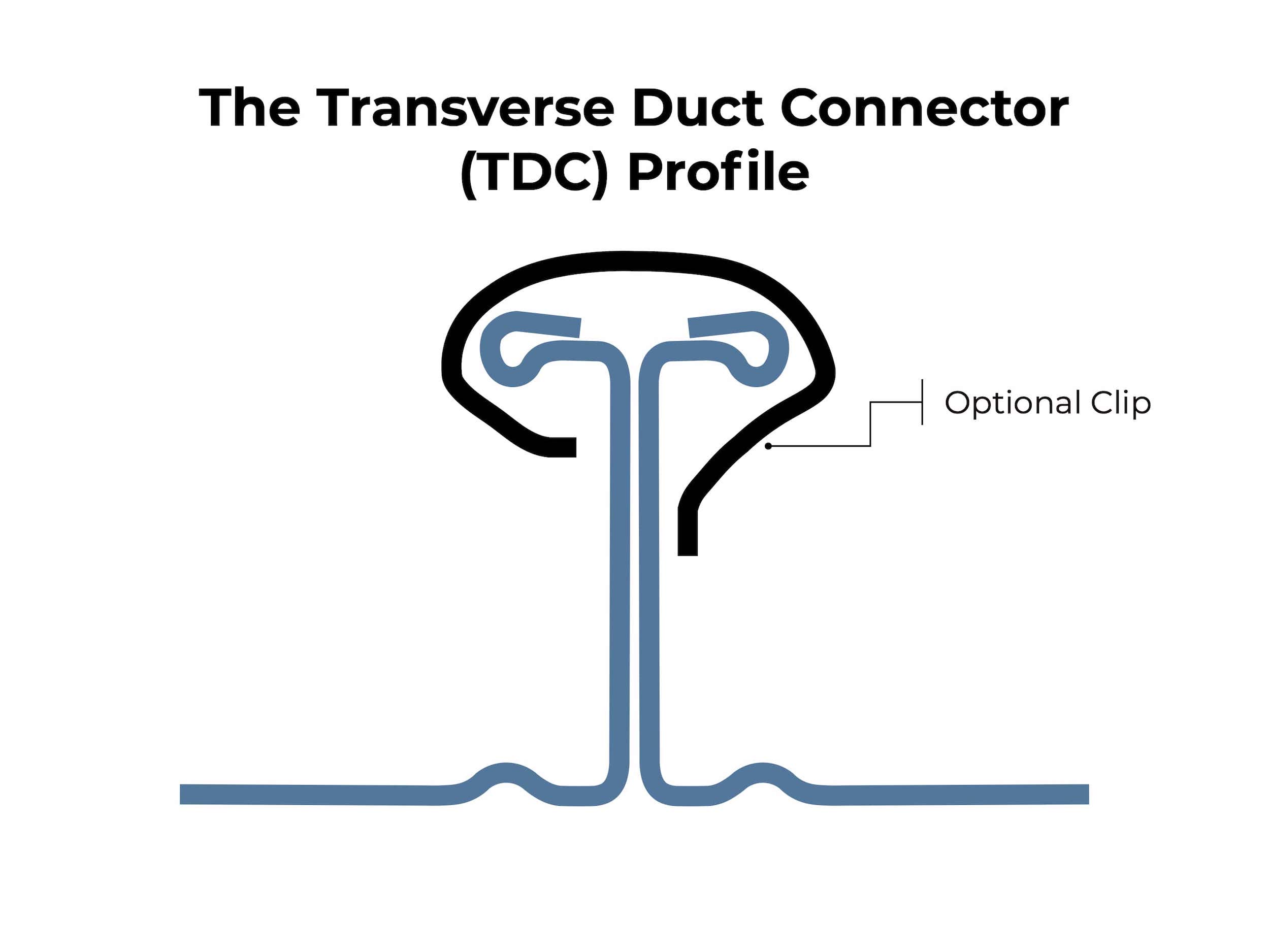

Yes, what they call a front end starter line today. And then over time that evolved, the pin became available, insulation became available. Then the bigger one was 1982, 3, 4? Transverse duct connector.

David:

But there was a … There’s an interesting story here because Welty Way, at the time, was only doing the coil processing and the notching. They did not do any roll forming. And-

John:

Yeah. That was all being done at Lockformer.

David:

All being done at Lockformer. And Welty joined forces with George Lamberson at Lockformer, Leo Gayle, engineering over there, and Bill Truska, head of sales. They joined together with Cutie Miskell at Welty, and had a … I don’t know in terms of … How it was in finance, but actually, Welty could take an order for a new line and sell the lock from a part, and they’d bought it from Lockformer. Well, Lockformer could do it themselves, too.

But it was a joint effort between Lockformer’s roll forming ability and Welty’s coil processing. And they merged that together, which was the first really significant line. Again, 1970, ’71.

But the insulation that came in ’73, one of the biggest problems was adding insulation onto that. That was an interesting story because they tried to join forces with Lockformer again, to do what became the Insomatic and Lockformer backed out of it because George Lamberson was afraid of selling a machine that used solid-based adhesives, and a fire problem on the line. Backed out of it and dumped it back into Welty. Roger Welty went out and visited a contractor in Murfreesberg, Tennessee, that had actually developed it, that machine.

But I could see it in 1970, and told Roger, “You ought to go down and take a look at this.” He bought the rights of the machine, and it’s basically not much changed since.

John:

Interesting.

David:

That’s how that whole thing came together. And then, really, not much between maybe the mid-’70s until the little TDC after that.

Mike:

Yeah. The mid-’80s was game-changing for two reasons, from what I understand. One was the rolled on flange, TDC, TDF connector. But I think the more industry changing revolutionary tool was the plasma cutter.

John:

Absolutely.

Mike:

That changed the entire industry for a lot of reasons. Automation was one. Craft was another. It started to take craft out of the industry because it did everything for you as far as downloading, it’d cut sheets, and numeric designs, things of that nature.

John:

And when you [crosstalk 00:08:37]. When you say craft, you’re talking about the actual snipping of the metal and that trade skill?

Mike:

Yeah. Being able to layout a fitting. If you find somebody today, that can do that, he’s retired.

John:

Yeah. No. We recently, I was talk … I don’t remember who it was. I had a guy in the lobby at the factory in Iowa. There’s a bunch of different fittings in the lobby there. They were talking about that. “This doesn’t look that complicated.” And I’m like, “If you unfolded this, you would not recognize what you are looking at.”

Mike:

When you traveled the shops, you’d see patterns, hundreds.

John:

And they’re all arra … The shape is a difficult to draw and a difficult to scribe out shape and cut. It takes a lot of skill.

David:

There’s a lot of geometry.

John:

And there’s a lot of geometry involved in that.

David:

There’s a lot of … Yeah.

John:

When we talked about, in a previous podcast, I think we discussed about the stickers. The stickers were putting some of that knowledge and the information right there, that could hand to the guy in the shop in order to make that thing. And then, now talking about the place, the plasma table in the ’80s, it then cut. Instead of just giving you a sticker, it actually cut the shape right out of the steel. Is that right?

Mike:

Correct. Correct, from a download, from a cam.

David:

Not to belabor this, but the ’80s, if you look back on the past 50 years, was definitely the decade. You had the first slide on and then TDC for your joint connections. Then you added the plasma cutting tables.

You actually … Another very big significant was the development of water-based adhesives. It was all solvent-based at the time, which was had environmental issues, fire problems on the line. And then, it went to water-based.

And then the last thing, again, was the introduction of the computerized cam cad systems. So those were four huge events that changed this industry.

Mike:

Yeah, and I think that created some issues to with architects and engineers when it came to roll flange versus sub long flange. There was a lot of arguments, you could say about, between building owners and architects, as to which one to specify and use.

And SMACNA decided to make a choice on that in 1995, and implemented the roll on flange into the DCS, which also implemented tie rod construction for mid-panel, end panel reinforcement, which cleaned everything up. It really did from a duct construction.

David:

Duct construction.

John:

What were they connecting the duct with prior to that?

Mike:

It would be slip on flange, could be duct bait.

John:

Like a duct [crosstalk 00:10:51]-

Mike:

Or TDC (Transverse Duct Connector), TDF (Transverse Duct Flange). Roll formed flange. That was the constant battle, which one was going to be spec’d and which one was better and which one was going to be used. Owners and architects and building owners, they all argued about it.

I think, the story I heard, SMACNA finally had to make a decision, and they made that decision to go with the Lockformer TDC, rolled form flange, and mid-panel, end panel tie rod construction.

John:

Now, has the design of that flange changed much since then, or has that pretty much stayed the same?

Mike:

No. The functional criteria is the same. We still use the same data as far as specifications that we tested with back in ’85, I would think. Something like that.