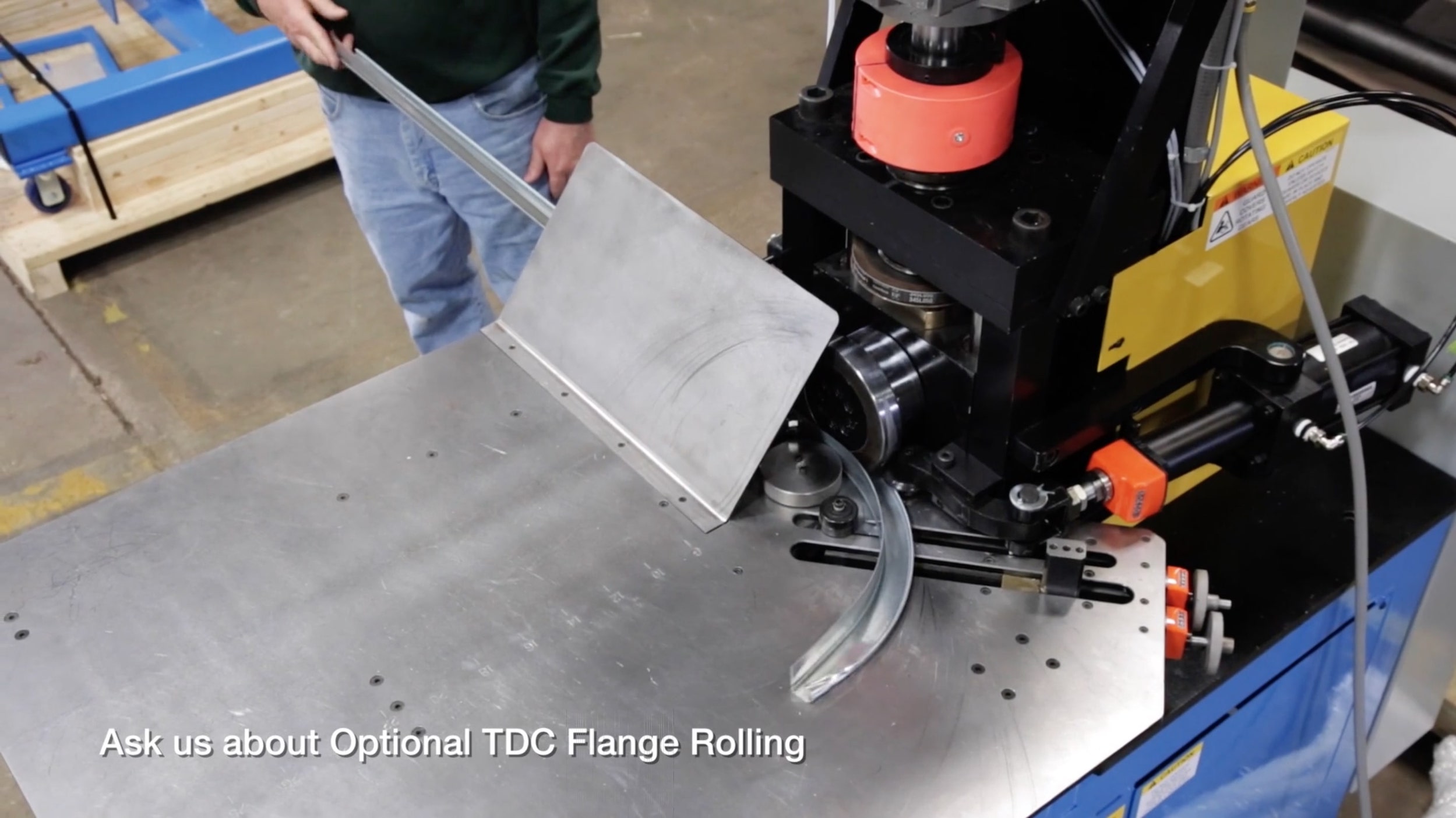

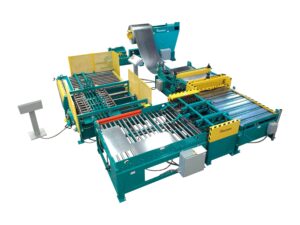

Lockformer Flanger 2.7 Flanging Machine

The diverse Lockformer Flanger 2.7 Flanging Machine produces either straight angle or flared angle round and oval flanges for a variety of uses. The Flanger 2.7 is filled with operator friendly features such as a touch screen PLC control and the ability to save and recall round and oval parameters for fast and easy production of duplicate parts.

Features

From Lockformer, the industry leader in HVAC sheet metal roll forming systems…

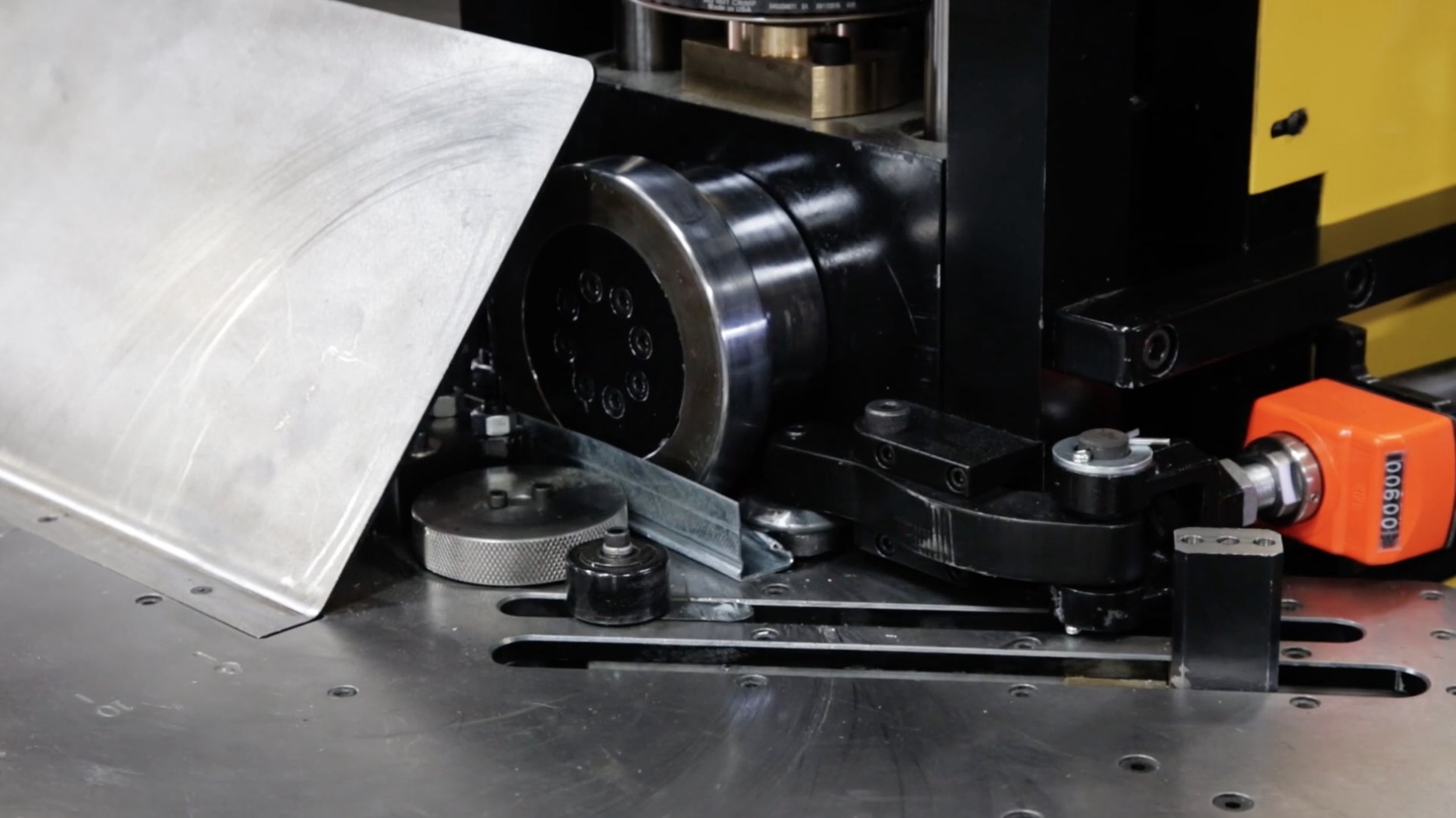

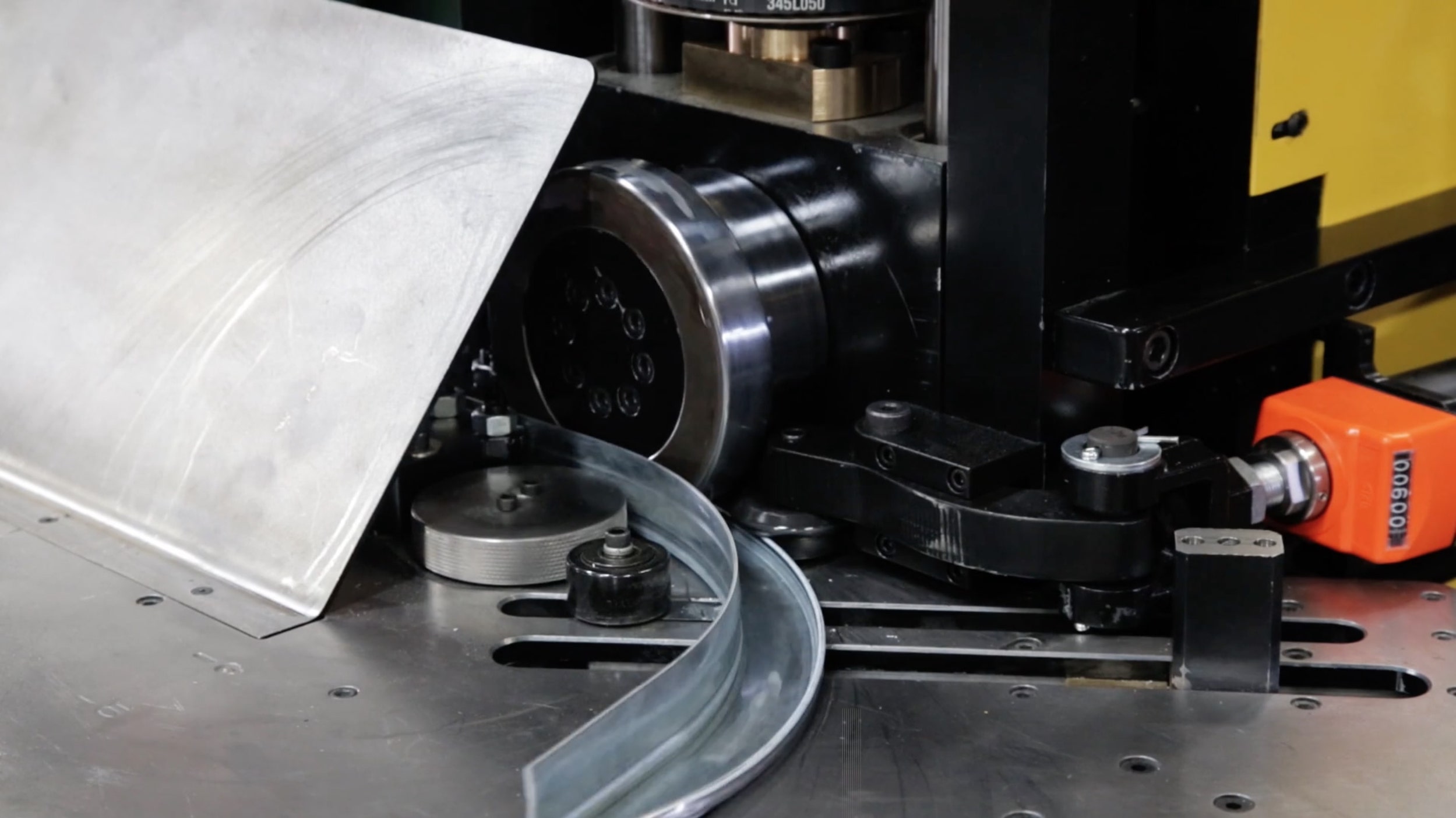

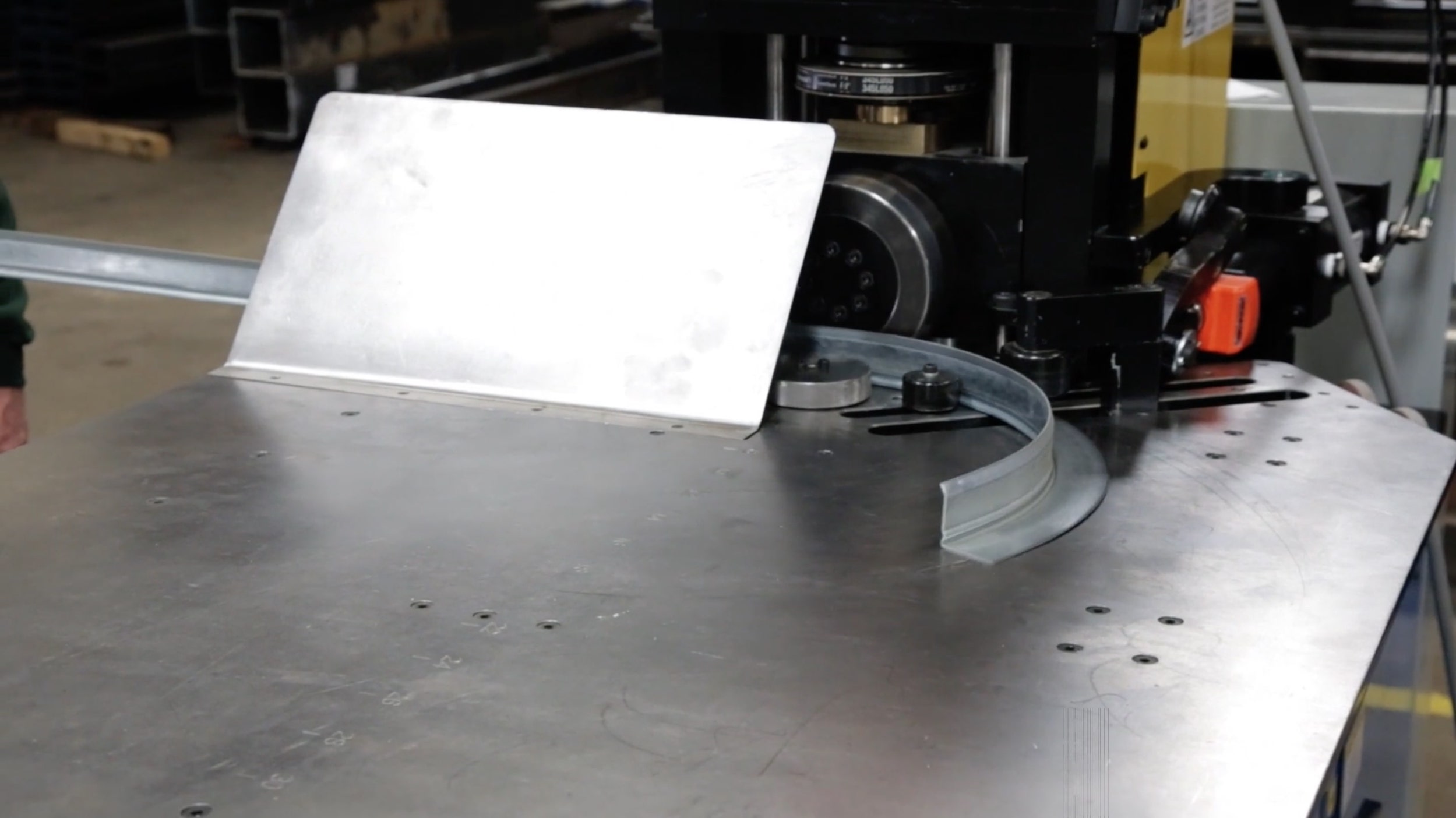

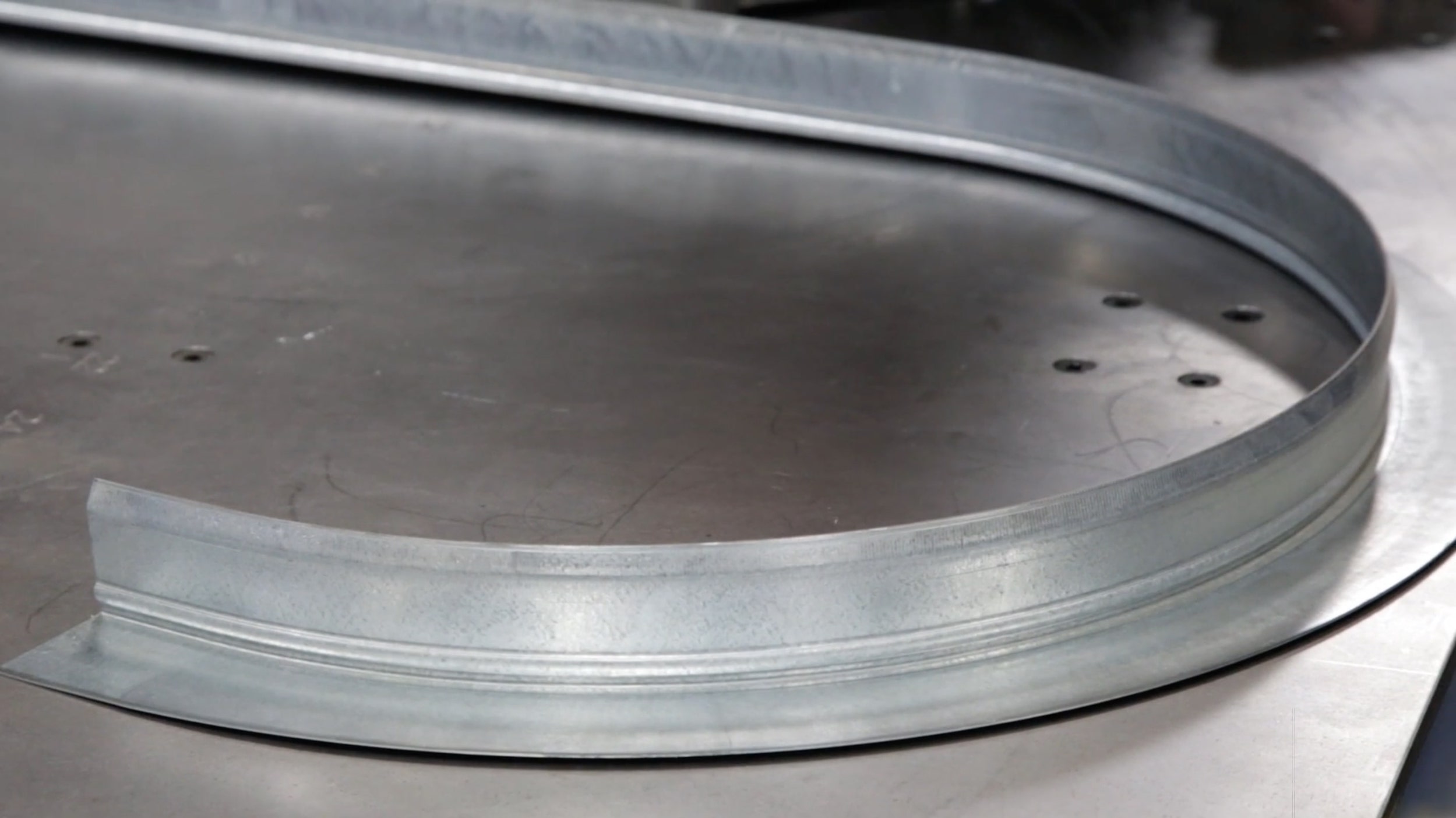

The Flanger 2.7 produces either straight angle or flared angle round and oval flanges for a variety of applications including ring connectors for HVAC spiral duct. The machine takes angled stock of up to 12 gauge material to create single-wall, double-wall, and oval spiral ring connectors from 8″ to 100″ in diameter for standard 90˚ flange. The Lockformer Flanger 2.7 also features operator-friendly touch screen PLC controls for easy operation and the ability to save and recall round and oval parameters for fast and easy production of duplicate parts.While the Lockformer Flanger 2.7 can accept angled stock from a press brake, its impact on shop productivity comes when it’s used in conjunction with the Lockformer Angler 1.6 Machine — which not only produces 90˚ angled stock from coil stock, but also punches pilot holes for screws and cuts it to the desired length. Unlike a press brake which can only produce 10 ft. sections for a maximum 30-inch diameter ring, the Angler allows you to produce precisely the angled stock you need for any diameter rings — even larger than 30-inch round — without a secondary cutting or punching operation. The combination of the Lockformer Angler 1.6 and Flanger 2.7 truly maximizes shop productivity when producing spiral ring connectors.

Specifications

Model | Capacity | Diameter Range | Motor / Voltage | Air Consumption | Dimensions / Weight |

Lockformer Flanger 2.7 Flanging Machine | Up to 12 gauge | 8" - 100" for standard 90° flange | 13 hp (2 motors) | 1 CFM @100PSI | Length: 74" |